Production with Example

In the world of manufacturing and business, production is a key process that involves turning raw materials into finished products. This article will explore the concept of production, its importance, and provide examples to help you understand it better.

Key Takeaways:

- Production is the process of transforming raw materials into finished goods.

- Efficient production methods can lead to cost savings and increased profits.

- Examples of production include manufacturing automobiles, baking bread, and assembling electronics.

Understanding Production

Production is the process of transforming raw materials or components into finished products through a series of planned activities. It involves various stages, such as procurement, storage, processing, assembly, and packaging. The primary goal of production is to create products that meet customer demand while optimizing resources and minimizing costs.

**Efficient production methods** can lead to significant cost savings and increased profitability for businesses. By streamlining processes, reducing waste, and improving the overall efficiency of production lines, companies can produce more goods at a lower cost, thus gaining a competitive advantage in the market.

Types of Production

There are three main types of production: **job production**, **batch production**, and **mass production**.

Job Production

In job production, products are created individually, and each item is tailored to meet specific customer requirements. This method is commonly used in industries like bespoke tailoring, custom furniture, and one-of-a-kind jewelry. Job production allows for high levels of customization, but it can be time-consuming and costly due to the need for individual attention to each product.

*Job production enables artisans to showcase their craftsmanship and create unique masterpieces.*

Batch Production

In batch production, a predetermined quantity of identical products is produced at a time. It involves setting up a production line to manufacture a specific number of items before moving on to the next batch. This method is commonly used in industries like food processing, pharmaceuticals, and clothing manufacturing. Batch production allows for better economies of scale compared to job production and offers a balance between customization and efficiency.

*Batch production enables companies to efficiently produce a variety of products without the need for complete customization.*

Mass Production

Mass production involves the continuous production of large quantities of standardized products. It often utilizes automated systems and assembly lines to achieve high-volume output. Mass production is commonly seen in industries such as automobile manufacturing, electronics, and consumer goods. This method allows for the production of goods at a significantly lower cost per unit but offers little room for customization.

*Mass production revolutionized the manufacturing industry by enabling the production of goods on a massive scale, increasing affordability for consumers.*

Examples of Production

Let’s take a look at a few real-life examples to better understand the concept of production:

Automobile Manufacturing

Automobile manufacturing involves a complex production process that transforms various raw materials, such as steel, rubber, and plastics, into fully functional vehicles. The production line includes assembling different parts, such as the engine, chassis, body, and interior components, before the final product is ready for market.

Bakery

In a bakery, the production process turns basic ingredients like flour, water, yeast, and sugar into delicious bread, pastries, and cakes. The dough is mixed, kneaded, shaped, and baked to yield the final products that are then packaged and sold to customers.

Electronics Assembly

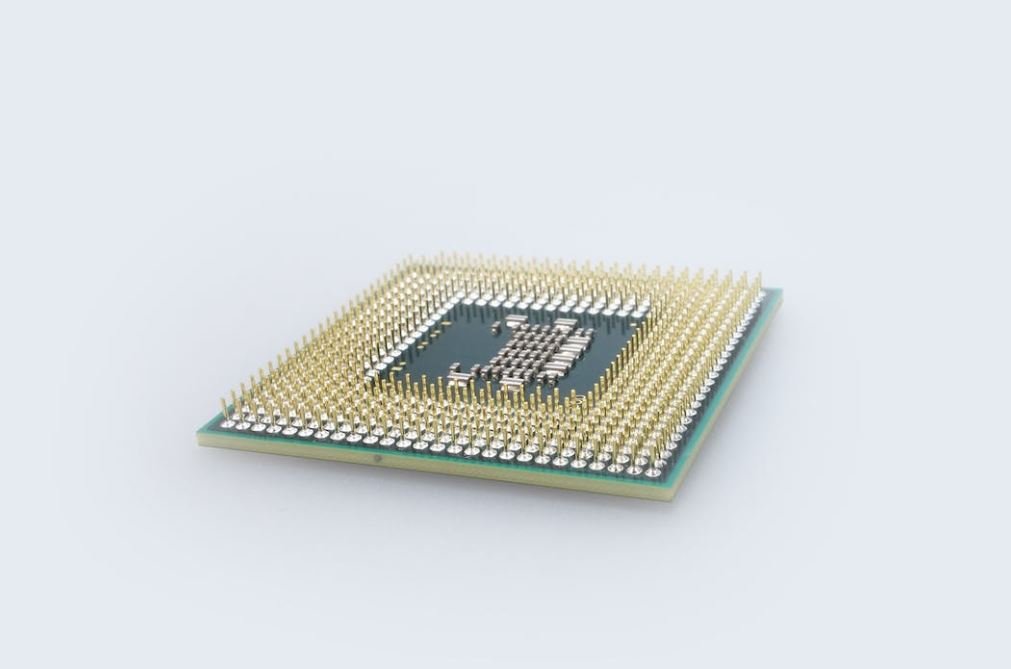

In electronics manufacturing, raw components such as circuit boards, solder, resistors, and capacitors are assembled to create electronic devices like smartphones, laptops, and televisions. This involves various stages, including soldering, wiring, and quality control, to ensure the final products are functional and meet the required specifications.

Benefits of Efficient Production

Efficient **production methods** offer several benefits for businesses:

- Reduced costs by minimizing waste and optimizing resources.

- Increased productivity and output.

- Improved quality control and customer satisfaction.

- Shorter lead times, enabling faster delivery to customers.

- Competitive advantage by offering better prices or higher quality products.

Conclusion

Production is a vital element of businesses across various industries. By understanding different production methods and implementing efficient processes, companies can produce goods that meet customer requirements while maximizing profits. Whether it’s manufacturing automobiles, baking bread, or assembling electronics, the production process plays a significant role in bringing products to market and satisfying consumer demands.

Common Misconceptions

Misconception 1: Production is only about manufacturing goods

One of the common misconceptions about production is that it only pertains to the physical manufacturing of goods. However, production encompasses a much broader scope. It involves the entire process of creating and delivering goods and services to meet customer demands. From identifying customer needs to designing, planning, and delivering products, production plays a significant role.

- Production involves more than just manufacturing

- It encompasses the entire supply chain process

- Production includes designing and planning as well

Misconception 2: Production is a standalone department

Another misconception is that production is a standalone department within an organization. In reality, production collaborates closely with other departments such as procurement, marketing, and sales to ensure a seamless flow of operations. Effective communication and coordination between departments are crucial for efficient production processes. Emphasizing cross-functional collaboration helps optimize productivity and minimize bottlenecks.

- Production works in tandem with other departments

- It requires cross-functional coordination

- Collaboration enhances overall productivity

Misconception 3: Production is solely responsible for quality control

Quality control is often perceived as the sole responsibility of the production department. However, ensuring product quality is a collective effort involving various stakeholders. Quality control should be present throughout the entire production process, from raw material procurement to final product delivery. Different departments need to work together to establish and maintain quality standards and control mechanisms.

- Quality control is a joint effort

- It extends beyond the production department

- Collaborative quality control enhances product integrity

Misconception 4: Production is only about maximizing output

There is a misconception that production is solely focused on maximizing output and productivity. While efficiency and productivity are important aspects of production, they are not the only factors to consider. Production also involves balancing quality, cost, and timeliness. Striking the right balance is crucial to ensure customer satisfaction and long-term business success.

- Production involves more than just output maximization

- Quality, cost, and timeliness are equally important

- Balancing all factors is essential for overall success

Misconception 5: Production is a separate stage in the product life cycle

Some people mistakenly view production as a distinct stage in the product life cycle. However, production is an ongoing process that spans multiple stages, from product conceptualization to disposal. It starts with research and development, followed by design, production, distribution, and after-sales support. Recognizing production as an integral part of the entire life cycle helps optimize operations and deliver value to customers.

- Production extends across multiple stages

- It starts with research and development

- Production is present throughout the product life cycle

Production Statistics of the Top 10 Countries in the Automotive Industry

The automotive industry is a vital sector in the global economy. This table provides an overview of the production statistics in the top 10 countries, showcasing their contributions to this thriving industry.

| Country | Annual Vehicle Production (in millions) | Percentage of Global Production |

|---|---|---|

| China | 25.2 | 29% |

| United States | 11.3 | 13% |

| Japan | 8.7 | 10% |

| Germany | 5.1 | 6% |

| India | 4.3 | 5% |

| Mexico | 4.1 | 5% |

| Brazil | 3.8 | 4% |

| South Korea | 3.7 | 4% |

| Spain | 2.8 | 3% |

| Canada | 2.7 | 3% |

Comparison of Average Hourly Wages in Manufacturing

When examining international manufacturing wages, disparities can have a significant impact. This table illustrates the average hourly wages in different countries, highlighting the varying labor costs associated with production.

| Country | Average Hourly Wage (in USD) |

|---|---|

| Germany | 27.50 |

| United States | 22.00 |

| Australia | 19.50 |

| China | 4.00 |

| India | 1.50 |

Trends of Global Smartphone Production

Smartphones have revolutionized the way we communicate, and their production continues to grow exponentially. This table depicts the trends of global smartphone production from the year 2015 to 2020.

| Year | Smartphone Production (in millions) |

|---|---|

| 2015 | 1,300 |

| 2016 | 1,500 |

| 2017 | 1,800 |

| 2018 | 2,100 |

| 2019 | 2,500 |

| 2020 | 3,000 |

Comparison of Energy Sources Used for Power Generation

As countries seek to reduce their carbon footprint, the energy sources they rely on for power generation vary significantly. This table presents a comparison of the percentage of energy derived from different sources in selected countries.

| Country | Percentage of Energy Sources |

|---|---|

| United States |

|

| Germany |

|

| China |

|

Global Coffee Consumption by Country

Coffee is one of the most widely consumed beverages worldwide. This table showcases the top coffee-consuming countries and their annual coffee consumption in millions of bags.

| Country | Annual Coffee Consumption (in millions of bags) |

|---|---|

| Brazil | 64 |

| United States | 26 |

| Germany | 16 |

| Japan | 8 |

| Italy | 6 |

Impact of Climate Change on Crop Yields

Climate change poses a significant threat to global food security. This table examines the potential impact of temperature increases on crop yields, highlighting the percentage reduction in yield for selected crops in different temperature scenarios.

| Temperature Scenario (°C) | Wheat | Rice | Maize |

|---|---|---|---|

| 1.5 | 6% | 5% | 4% |

| 2.0 | 8% | 7% | 6% |

| 3.0 | 14% | 12% | 10% |

Comparison of Tourism Revenue in Popular Destinations

Tourism plays a significant role in the economic growth of various countries. This table compares the revenue generated from international tourism in different popular destinations.

| Destination | Tourism Revenue (in billions of USD) |

|---|---|

| France | 60.7 |

| United States | 53.0 |

| Spain | 52.5 |

| China | 45.3 |

| Italy | 41.2 |

Employment in the Tech Industry by Gender

Gender diversity in the tech industry has become a prominent topic of discussion. This table highlights the percentage of women employed in the tech industry in different countries.

| Country | Percentage of Women Employed |

|---|---|

| Sweden | 27% |

| United States | 24% |

| India | 20% |

| South Korea | 18% |

| Japan | 14% |

Comparison of Internet Speeds in Selected Countries

Fast and reliable internet connectivity is crucial for modern societies. This table compares the average internet speeds in selected countries, indicating the download and upload speeds in megabits per second (Mbps).

| Country | Average Download Speed (Mbps) | Average Upload Speed (Mbps) |

|---|---|---|

| South Korea | 261 | 82 |

| Norway | 238 | 79 |

| Switzerland | 218 | 65 |

| Singapore | 198 | 89 |

| Sweden | 173 | 60 |

Production plays a pivotal role in various industries, shaping economies and influencing global trends. This article explored production statistics, labor wages, technology, energy sources, and other elements. By examining these tables, we gain insights into the vastness and dynamics of production, enabling us to make informed decisions and drive progress in the ever-evolving world of production.

Frequently Asked Questions

What is production?

Production refers to the process of combining various resources, such as labor, machinery, and raw materials, to manufacture goods or provide services. It involves the entire production lifecycle, from planning and designing to manufacturing and distribution.

What are the different types of production?

The different types of production include:

- Mass production: Large-scale production of standardized goods.

- Custom production: Tailored production of individualized goods.

- Batch production: Production in batches, where each batch consists of a specific quantity of products.

- Continuous production: Uninterrupted production system often used in industries like oil refining or electricity generation.

- Job production: Production of unique, one-off products according to specific customer requirements.

What is the production process?

The production process generally involves the following steps:

- Idea Generation

- Product Design and Development

- Raw Material Procurement

- Assembly or Manufacturing

- Quality Control

- Packaging

- Distribution

- Sales and After-Sales Service

What are the key objectives of production?

The key objectives of production include:

- Optimizing resource utilization

- Maximizing productivity and efficiency

- Ensuring quality control

- Meeting customer demand

- Minimizing costs

- Increasing profitability

How can production efficiency be improved?

Production efficiency can be improved by:

- Implementing lean manufacturing techniques

- Using automation and advanced technology

- Optimizing production workflows

- Streamlining supply chain management

- Investing in employee training and development

- Regularly assessing and improving processes

What is the role of quality control in production?

Quality control in production ensures that products meet the desired quality standards. It involves performing inspections, tests, and analyses at various stages of the production process to identify defects or deviations. By maintaining quality, businesses can enhance customer satisfaction, minimize rework or rejection, and build a strong brand reputation.

What are the key challenges in production?

The key challenges in production include:

- Managing supply chain complexities

- Maintaining consistent product quality

- Adapting to changing customer demands

- Minimizing production downtime

- Ensuring worker safety

- Managing environmental sustainability

What factors affect production costs?

Several factors can affect production costs, such as:

- Raw material prices

- Labor wages

- Energy costs

- Manufacturing technology and equipment

- Transportation and logistics expenses

- Regulatory compliance

How can production waste be minimized?

Production waste can be minimized by:

- Implementing lean production practices

- Optimizing inventory management

- Employing recycling and reuse strategies

- Using energy-efficient processes

- Training employees on waste reduction techniques

- Monitoring and analyzing production data

What role does technology play in production?

Technology plays a crucial role in production, enabling businesses to:

- Automate repetitive tasks

- Enhance productivity and efficiency

- Improve product quality

- Optimize inventory management

- Track and analyze production data

- Facilitate communication and collaboration