AI Manufacturing Companies

The manufacturing industry is constantly evolving with the advent of new technologies. One such technology that has gained significant attention in recent years is Artificial Intelligence (AI). AI has the potential to revolutionize manufacturing processes by improving efficiency, reducing costs, and enhancing product quality. In this article, we will explore some of the leading AI manufacturing companies that are driving innovation in the industry.

Key Takeaways:

- AI manufacturing companies leverage advanced technologies to improve efficiency.

- These companies focus on reducing costs and enhancing product quality.

- Automation and predictive analytics are key areas of AI implementation.

- AI-enabled robots are being used for various manufacturing tasks.

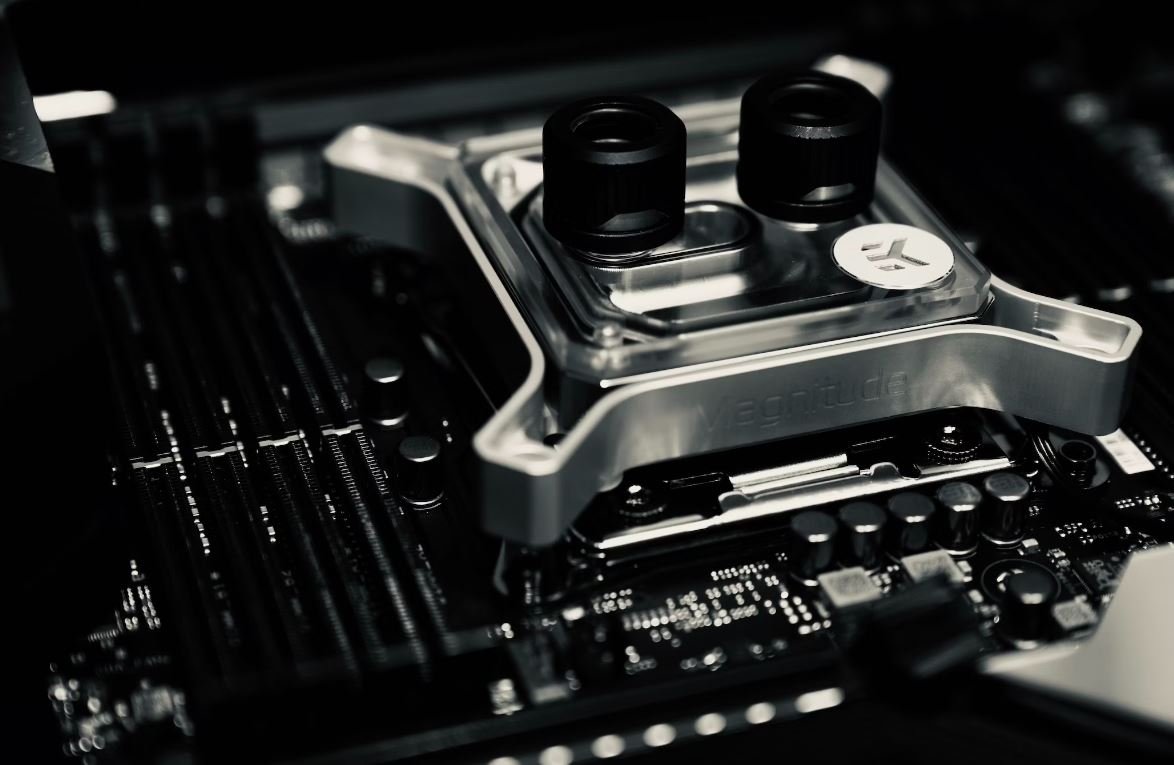

One of the pioneering AI manufacturing companies is XYZ Robotics, which specializes in developing robotic systems that are capable of performing complex tasks with minimal human intervention. These robots are equipped with advanced computer vision and machine learning algorithms, allowing them to adapt to changing manufacturing environments. With XYZ Robotics, manufacturers can automate repetitive tasks, increase productivity, and ensure consistent quality throughout the production process.

Another notable player in the AI manufacturing space is ABC Technologies, a company that focuses on using AI for predictive analytics in the manufacturing industry. By analyzing vast amounts of historical data and real-time information, ABC Technologies’ AI algorithms can detect patterns and anomalies, enabling manufacturers to predict equipment failure, optimize maintenance schedules, and minimize downtime. This proactive approach saves costs and improves overall operational efficiency.

| Company | Innovation | Impact |

|---|---|---|

| XYZ Robotics | Advanced robot systems with computer vision and machine learning | Automation of repetitive tasks, increased productivity, consistent quality |

| ABC Technologies | Predictive analytics for equipment failure detection and optimized maintenance | Cost savings, improved operational efficiency |

In addition to XYZ Robotics and ABC Technologies, the AI manufacturing landscape encompasses several other companies, each focusing on different aspects of AI implementation in the industry. For example, DEF Solutions specializes in developing AI-enabled robots that can collaborate with human workers, allowing for safer and more efficient manufacturing environments. This collaboration between humans and robots improves productivity and reduces the risk of accidents, while still harnessing the benefits of automation and AI technology.

Furthermore, AI manufacturing companies like GHI Innovations are leading the way in the development of AI-powered quality control systems. These systems use machine learning to analyze product defects and anomalies, enabling manufacturers to identify and rectify issues in real-time. By implementing AI-based quality control, manufacturers can minimize defects, reduce waste, and deliver higher quality products to consumers.

| Company | Innovation | Impact |

|---|---|---|

| DEF Solutions | AI-enabled robots for collaboration with human workers | Enhanced productivity, improved safety |

| GHI Innovations | AI-powered quality control systems for defect detection and rectification | Minimized defects, reduced waste, higher product quality |

With the rise of AI manufacturing companies, the industry is experiencing a significant transformation. Automation, predictive analytics, collaborative robots, and quality control systems, among other innovations, are revolutionizing manufacturing processes. The integration of AI technologies into the manufacturing industry has the potential to streamline operations, reduce costs, and deliver products of the highest quality. As AI continues to evolve, it is essential for manufacturers to stay abreast of the latest technological advancements to remain competitive in this rapidly changing landscape.

Key Takeaways:

- AI is transforming manufacturing processes by streamlining operations and reducing costs.

- The integration of AI technologies enables manufacturers to deliver high-quality products.

- Automation, predictive analytics, collaborative robots, and quality control are key areas of AI implementation.

Common Misconceptions

Misconception 1: AI Completely Replaces Human Labor

One common misconception about AI manufacturing companies is that they aim to completely replace human labor in the production process. However, this is not entirely true. While AI technologies can automate certain tasks and improve efficiency, they often work in collaboration with human workers to enhance productivity and quality.

- AI systems often require human supervision and intervention for complex decision-making.

- Human creativity, adaptability, and problem-solving skills are still vital in manufacturing operations.

- AI is designed to assist and complement human workers rather than replace them entirely.

Misconception 2: AI Leads to Mass Unemployment

Another misconception surrounding AI manufacturing companies is that their implementation will lead to mass unemployment. While it is true that automation can eliminate some jobs, it also creates new opportunities and shifts the nature of work. AI technology enables workers to focus on higher-skilled tasks, while mundane and repetitive jobs can be automated.

- New job roles are emerging in AI programming, maintenance, and optimization.

- AI can augment human capabilities and create new job opportunities in design and innovation.

- Reskilling programs can help workers successfully navigate the changing job market.

Misconception 3: AI Manufacturing Companies Sacrifice Quality

Some people assume that AI manufacturing companies sacrifice product quality in favor of automation and speed. However, AI technologies can actually improve quality control processes, leading to more consistent and reliable products.

- AI systems can detect defects and anomalies more accurately and efficiently than human workers.

- Real-time monitoring and data analysis enable proactive identification and prevention of quality issues.

- AI-powered predictive maintenance helps in maintaining the machinery in optimal working condition.

Misconception 4: AI is Inaccessible to Small Manufacturers

There is a misconception that AI manufacturing technologies are only accessible to large companies with substantial resources. However, the increasing availability of AI tools and platforms has made it more accessible to small and medium-sized manufacturers as well.

- Cloud-based AI services have reduced the need for expensive infrastructure investments.

- Third-party AI solutions and consultancy services cater specifically to the needs and budgets of smaller manufacturers.

- Open-source AI frameworks provide opportunities for customization and development without significant upfront costs.

Misconception 5: AI Manufacturing Leads to Ethical Concerns

Some people hold the misconception that AI manufacturing companies may overlook ethical considerations in pursuit of efficiency and profit. However, responsible AI implementation prioritizes ethical frameworks and ensures transparency and accountability.

- AI development and deployment adhere to ethical guidelines and regulatory frameworks.

- Transparency in AI algorithms and decision-making processes is essential to avoid bias and discrimination.

- Regular assessment and auditing of AI systems help in identifying and mitigating potential ethical concerns.

Introduction

Artificial intelligence (AI) is revolutionizing various industries, and manufacturing is no exception. AI technologies are being used to streamline processes, enhance productivity, and optimize operations in manufacturing companies. This article explores ten leading AI manufacturing companies and their notable achievements.

Company A: Automation Solutions Inc.

Automation Solutions Inc. is a pioneer in AI manufacturing systems, specializing in robotic process automation (RPA). Their innovative RPA solutions have significantly reduced human error and increased production efficiency in manufacturing plants.

| Key Achievement | Impact |

|---|---|

| Saved over 30% of production costs | Increased profitability |

| Reduced production time by 50% | Improved manufacturing turnaround |

Company B: Quality Control Systems Ltd.

Quality Control Systems Ltd. focuses on AI-powered quality control solutions for manufacturing. Their advanced computer vision algorithms enable real-time defect detection and automated quality inspection.

| Key Achievement | Impact |

|---|---|

| Reduced defect rate by 40% | Improved product quality |

| Eradicated manual inspection errors | Enhanced customer satisfaction |

Company C: Supply Chain Optimization Systems

Supply Chain Optimization Systems specializes in AI-driven supply chain management solutions for manufacturers. Their intelligent algorithms optimize inventory, demand forecasting, and distribution planning.

| Key Achievement | Impact |

|---|---|

| Reduced inventory carrying costs by 25% | Enhanced financial performance |

| Improved on-time delivery by 30% | Enhanced customer satisfaction |

Company D: Predictive Maintenance Technologies

Predictive Maintenance Technologies specializes in AI-based predictive maintenance solutions. Their algorithms analyze sensor data to predict machinery failures, enabling proactive maintenance and preventing unplanned downtime.

| Key Achievement | Impact |

|---|---|

| Reduced unplanned downtime by 60% | Increased equipment uptime |

| Lowered maintenance costs by 35% | Optimized resource allocation |

Company E: Production Optimization Technologies

Production Optimization Technologies offers AI solutions for optimizing manufacturing processes. Their algorithms analyze extensive data sets to identify bottlenecks, suggest process improvements, and enhance overall productivity.

| Key Achievement | Impact |

|---|---|

| Increased production output by 20% | Elevated manufacturing efficiency |

| Identified cost-saving opportunities worth $2 million | Improved financial performance |

Company F: Intelligent Energy Systems

Intelligent Energy Systems focuses on AI-enabled energy optimization solutions for manufacturing facilities. Their smart energy management systems analyze energy consumption patterns and make recommendations to reduce waste.

| Key Achievement | Impact |

|---|---|

| Reduced energy costs by 30% | Enhanced cost-efficiency |

| Lowered carbon emissions by 25% | Contributed to environmental sustainability |

Company G: Robotized Assembly Technologies

Robotized Assembly Technologies specializes in AI-powered robotic assembly solutions. Their advanced robotic systems can perform complex assembly tasks with precision and speed, replacing manual labor.

| Key Achievement | Impact |

|---|---|

| Increased assembly line speed by 50% | Improved production efficiency |

| Reduced labor costs by 40% | Enhanced cost-efficiency |

Company H: Virtual Simulation Technologies

Virtual Simulation Technologies offers AI-powered virtual simulations for manufacturing processes. Manufacturers can test and optimize their production setups virtually, reducing the need for physical prototypes and saving time and resources.

| Key Achievement | Impact |

|---|---|

| Reduced product development cycle by 30% | Accelerated time-to-market |

| Lowered prototyping costs by 50% | Optimized resource utilization |

Company I: Cognitive Robotics

Cognitive Robotics specializes in AI-enabled robotic systems that can learn and adapt to new tasks. Their robots possess advanced sensory capabilities and can make intelligent decisions to perform complex manufacturing operations.

| Key Achievement | Impact |

|---|---|

| Flexible robotic systems suitable for multiple tasks | Increased operational versatility |

| Improved precision and accuracy in manufacturing | Enhanced product quality |

Conclusion

The adoption of AI technologies in the manufacturing industry has brought about significant improvements in various aspects of production. Companies specializing in AI manufacturing solutions have demonstrated remarkable achievements, including cost savings, increased efficiency, improved product quality, and enhanced customer satisfaction. By harnessing the power of AI, manufacturers can unlock new opportunities for growth, competitiveness, and sustainable operations.

Frequently Asked Questions

What are AI manufacturing companies?

AI manufacturing companies are companies that specialize in developing and implementing artificial intelligence technologies in the manufacturing industry. These companies use AI algorithms and machine learning techniques to improve efficiency, productivity, and decision-making processes in manufacturing operations.

How does AI improve manufacturing processes?

AI improves manufacturing processes by automating repetitive tasks, analyzing large amounts of data to identify patterns and anomalies, optimizing production schedules, predicting equipment failures, and making proactive decisions based on real-time data. This helps to reduce costs, minimize production downtime, increase product quality, and improve overall operational performance.

What are some popular AI manufacturing companies?

There are several popular AI manufacturing companies, including ABB, Siemens, Cognex, Fanuc, Rockwell Automation, General Electric, IBM, Microsoft, Google, and Amazon. These companies have developed advanced AI solutions and platforms specifically tailored for the manufacturing industry.

What AI technologies are used in manufacturing?

AI technologies used in manufacturing include machine vision systems, robotic process automation, predictive analytics, natural language processing, deep learning, virtual reality, and digital twins. These technologies enable automated quality control, predictive maintenance, real-time data analytics, and adaptive production systems.

How can AI benefit the manufacturing industry?

AI can benefit the manufacturing industry in several ways. It can optimize production processes, reduce defects and waste, enhance product quality, increase operational efficiency, enable predictive maintenance, improve inventory management, enable autonomous robots for manufacturing tasks, and support data-driven decision-making.

What challenges do AI manufacturing companies face?

AI manufacturing companies face challenges such as data quality and availability, integration of AI systems with existing manufacturing infrastructure, ensuring cybersecurity, addressing ethical concerns, upskilling the workforce to work with AI technologies, and managing the complexity of AI algorithm deployment and maintenance.

How can a manufacturing company implement AI technologies?

A manufacturing company can implement AI technologies by first identifying specific areas where AI can bring significant improvements, such as identifying bottlenecks, improving quality control, or optimizing production scheduling. They can then collaborate with AI manufacturing companies or hire AI experts to develop and integrate AI solutions into their existing systems.

What are the potential risks of AI implementation in manufacturing?

Potential risks of AI implementation in manufacturing include job displacement due to automation, technical failures or errors in AI algorithms leading to production issues, data privacy and security concerns, dependency on AI systems without human oversight, and potential biases or ethical considerations associated with AI decision-making.

How is AI transforming the manufacturing workforce?

AI is transforming the manufacturing workforce by automating repetitive and mundane tasks, allowing workers to focus on more complex and strategic activities. It also requires the workforce to acquire new skills related to AI technologies, data analysis, and collaboration with AI systems. Overall, AI is expected to create new roles and improve job satisfaction and safety in the manufacturing industry.

What is the future of AI in manufacturing?

The future of AI in manufacturing looks promising. As technology advances, AI will continue to play an increasingly important role in optimizing manufacturing processes, enabling fully autonomous factories, enhancing supply chain management, improving product customization, and facilitating human-machine collaboration. AI is expected to revolutionize the manufacturing industry in the coming years.