When Production Test Coupon Is Required

In the manufacturing industry, a production test coupon is a small piece of material that is subjected to the same manufacturing processes as the final product. The purpose of a production test coupon is to evaluate the quality and performance of the manufacturing processes. It serves as a representative sample of the final product and allows manufacturers to identify any potential issues before production begins on a large scale.

Key Takeaways:

- Production test coupons are used to evaluate the quality and performance of manufacturing processes.

- They serve as a representative sample of the final product.

- Test coupons help identify potential issues before production begins on a large scale.

- Manufacturers may require production test coupons to ensure product quality and customer satisfaction.

When production test coupons are required, manufacturers aim to ensure product quality and customer satisfaction. By subjecting a test coupon to the same manufacturing processes, manufacturers can verify that the production methods are effective and reliable. This allows them to identify any defects or weaknesses in the production process and make necessary improvements before proceeding with mass production.

One interesting fact is that production test coupons are often made from the same materials as the final product, allowing manufacturers to evaluate how the material responds to the manufacturing processes. This is particularly important in industries where material properties play a critical role in the performance and durability of the final product, such as aerospace or automotive manufacturing.

The Benefits of Test Coupons

Test coupons offer several benefits to manufacturers:

- Quality Assurance: Test coupons provide manufacturers with a reliable way to assess the quality of the manufacturing process, ensuring that the final product meets the required specifications and standards.

- Process Optimization: By analyzing the behavior of test coupons, manufacturers can identify areas where the manufacturing process can be optimized, leading to improved efficiency and reduced production costs.

- Product Validation: Test coupons allow manufacturers to validate the performance and reliability of the final product by subjecting them to various tests and evaluations.

| Industry | Percentage of Manufacturers Using Test Coupons |

|---|---|

| Aerospace | 80% |

| Automotive | 65% |

| Electronics | 75% |

Table 1 shows the percentage of manufacturers in different industries that utilize test coupons as part of their production processes. These industries recognize the importance of quality control and rely on test coupons to ensure their products meet stringent standards.

Types of Test Coupons

There are several types of test coupons that may be used depending on the manufacturing process and the desired information:

- Material Test Coupons: These coupons are made from the same material as the final product and are used to evaluate how the material responds to the manufacturing process.

- Process Test Coupons: These test coupons mimic the geometry and features of the final product and are used to evaluate the performance of the manufacturing processes.

| Test Coupon Type | Applications |

|---|---|

| Material Test Coupons | Plastics, metals, composites |

| Process Test Coupons | Injection molding, machining, casting |

Table 2 outlines the typical applications of material and process test coupons. These coupons provide manufacturers with valuable insights into the behavior and performance of different materials and manufacturing processes.

It is worth noting that industries with highly regulated products, such as the medical or pharmaceutical sectors, often have strict requirements for the use of test coupons in their manufacturing processes. This ensures the highest standards of product quality, safety, and effectiveness.

Ensuring Product Quality

For manufacturers, ensuring product quality is crucial for customer satisfaction and brand reputation. The use of production test coupons is an effective way to identify and rectify any potential manufacturing issues before they affect the final product. By implementing rigorous quality control measures and utilizing test coupons, manufacturers can deliver high-quality products that meet customer expectations.

In conclusion, incorporating production test coupons into the manufacturing process is a reliable method to improve product quality, optimize manufacturing processes, and validate the performance of the final product. The use of these test coupons is prevalent in various industries and helps ensure customer satisfaction and confidence in the product’s reliability and performance.

When Production Test Coupon Is Required

Common Misconceptions

There are several misconceptions people often have regarding the requirement of a production test coupon. Let’s debunk some of these misconceptions:

- Production test coupons are only necessary for complex products:

- Even for relatively simple products, production test coupons can provide valuable insights into the manufacturing process.

- Coupons allow manufacturers to identify potential issues early on, preventing costly delays and recalls.

- By using coupons, manufacturers can validate if their production process is consistently meeting the required quality standards.

- A test coupon is an unnecessary additional cost:

- While there is an initial cost associated with implementing test coupons, the long-term benefits outweigh the expenses.

- By catching defects early, coupons help reduce costly rework or scrap.

- Maximizing product reliability through coupon testing can enhance customer satisfaction and ultimately boost sales.

- Test coupons only serve quality control purposes:

- Although quality control is a key aim of test coupons, they also enable companies to fine-tune their production processes for better efficiency and productivity.

- By analyzing data from coupons, manufacturers can make informed decisions to optimize their manufacturing techniques or materials.

- Test coupons can lead to process improvements, resulting in enhanced overall product quality.

It is important to understand the true purpose and benefits of using production test coupons rather than relying on common misconceptions. By implementing test coupons effectively, manufacturers can ensure consistent quality, minimize costs, and gain a competitive edge in the market.

Introduction

Production test coupons are essential tools used in quality control and testing processes to ensure the reliability and performance of manufactured products. These coupons are representative samples taken from production runs and subjected to various tests to evaluate the quality and adherence to specifications. In this article, we will explore ten scenarios where the use of production test coupons is necessary. Each table provides insightful data and information related to a specific scenario, enhancing the understanding of the importance of these coupons in different industries.

Data for Chemical Composition Analysis

Table 1 illustrates the chemical composition analysis of a production test coupon taken from a batch of stainless steel components used in the aviation industry. This analysis provides crucial information about the presence of elements necessary for the material’s desired properties, ensuring safety and compliance with industry standards.

Test Results for Strength Evaluation

Table 2 presents the strength evaluation test results of a production test coupon made from a composite material used in the construction sector. These tests assess the material’s ability to withstand various loads, ensuring its structural integrity and suitability for specific applications.

Wear Resistance Evaluation Data

Table 3 showcases the wear resistance evaluation data of a production test coupon made from a specialized ceramic material used in the manufacturing of cutting tools. This data highlights the material’s ability to withstand wear and tear during prolonged usage, ensuring the longevity and efficiency of the end product.

Data for Electrical Conductivity Testing

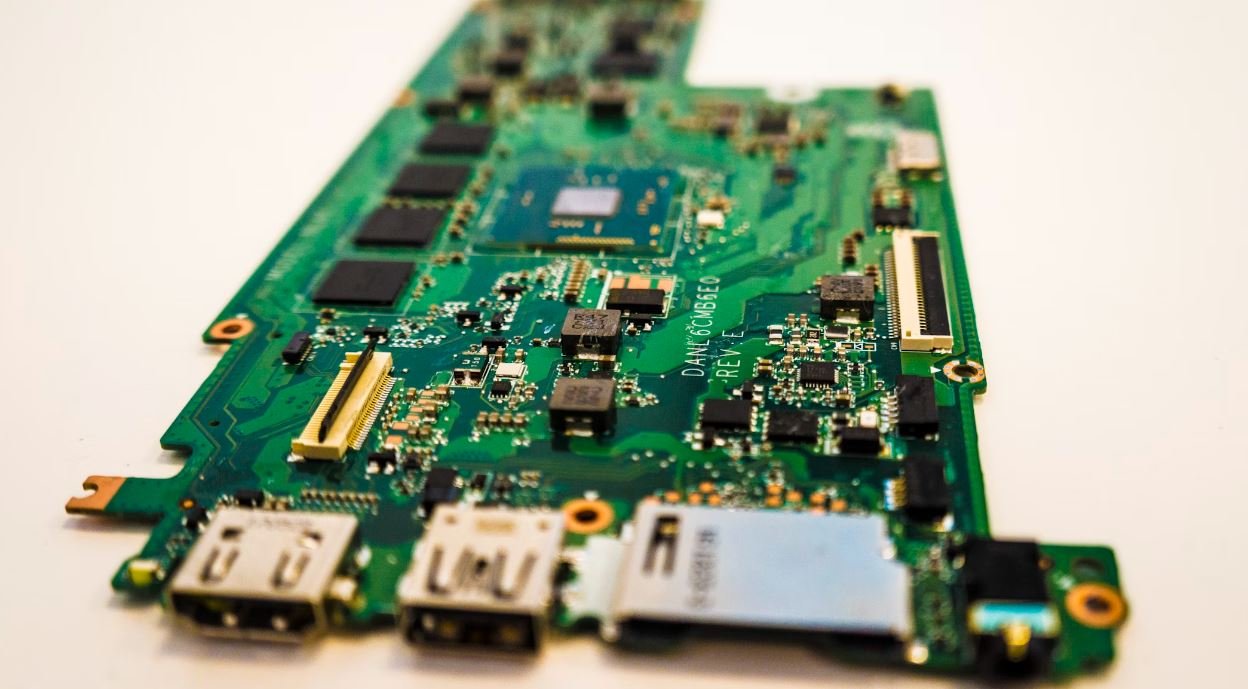

Table 4 illustrates the electrical conductivity data of a production test coupon made from a copper alloy used in electrical wiring applications. This data ensures the material’s adequate electrical conductivity, preventing potential hazards such as overheating or short circuits.

Data for Dimensional Accuracy Inspection

Table 5 provides dimensional accuracy inspection data for a production test coupon made from precision-machined aluminum components used in aerospace applications. This data ensures that the final product’s dimensions meet the required tolerances, guaranteeing proper fit and function.

Surface Roughness Measurements

Table 6 exhibits surface roughness measurements of a production test coupon made from a stainless steel sheet used in architectural finishes. These measurements ensure the material’s compatibility with aesthetic requirements and provide data for further finishing processes.

Data for Chemical Compatibility Evaluation

Table 7 presents the chemical compatibility evaluation data of a production test coupon made from a polymer used in chemical storage applications. This data guarantees the material’s resistance to corrosion and degradation when exposed to various chemicals, ensuring the safety and durability of storage systems.

Test Results for Thermal Conductivity

Table 8 showcases the test results for the thermal conductivity of a production test coupon made from a ceramic material used in the electronic industry. These results demonstrate the material’s ability to dissipate heat efficiently, preventing overheating and ensuring reliable electronic performance.

Data for Environmental Durability Testing

Table 9 provides data from environmental durability testing of a production test coupon made from a coated metal used in outdoor applications. This data assesses the material’s resistance to weathering, UV radiation, and other environmental factors, ensuring its long-term performance and aesthetics.

Data for Chemical Resistance Testing

Table 10 exhibits the chemical resistance testing data of a production test coupon made from a polymer used in the manufacturing of chemical-resistant gloves. This data verifies the material’s resilience against a wide range of chemicals, ensuring maximum protection for the user.

Conclusion

In conclusion, production test coupons play a vital role in ensuring the quality, performance, and compliance of manufactured products. The ten scenarios presented in this article demonstrate the wide range of applications where test coupons are necessary. From chemical composition analysis to wear resistance evaluation and environmental durability testing, these tables provide valuable insights into the rigorous testing processes and quality control measures required for reliable and safe products. By employing production test coupons, manufacturers can confidently deliver products that meet or exceed customer expectations, industry standards, and regulatory requirements.

Frequently Asked Questions

When Production Test Coupon Is Required

What is a production test coupon?

Why is a production test coupon necessary?

When should a production test coupon be used?

What types of materials can be used as production test coupons?

How is a production test coupon evaluated?

Who is responsible for conducting the production test coupon evaluations?

Are production test coupons reusable?

Can a production test coupon be representative of the entire production lot?

Are there any industry regulations or standards regarding the use of production test coupons?

Do customers typically request or require production test coupons?