Production Management Group

When it comes to managing the production process, a Production Management Group is an essential component for any business. This group is responsible for overseeing all aspects of production, from planning and organizing to controlling and coordinating. Their expertise ensures that production operations run efficiently and effectively, resulting in higher productivity and better quality products. In this article, we will explore the key responsibilities and benefits of a Production Management Group, as well as how they contribute to the overall success of a company.

Key Takeaways

- A Production Management Group is responsible for overseeing all aspects of the production process.

- They ensure that production operations run efficiently and effectively, resulting in higher productivity and better quality products.

- Their expertise contributes to the overall success of a company.

**One of the main responsibilities of a Production Management Group** is to plan and organize the production process. They work closely with other teams, such as engineering and marketing, to develop a production plan that aligns with the company’s goals and objectives. This involves determining the production schedule, identifying resource requirements, and establishing production targets. By **meticulously planning** each step of the process, they ensure that production operations are streamlined and executed in a timely manner.

**Another vital role of a Production Management Group** is to control and coordinate the production process. They monitor the progress of production operations, track key performance indicators (KPIs), and make adjustments as necessary to meet production targets. By **maintaining strict control** over the production process, they minimize delays, reduce waste, and optimize resource utilization. Their coordination efforts involve liaising with different departments and teams, ensuring a seamless flow between production stages.

**Efficiency and productivity are paramount** to a Production Management Group. They continuously analyze the production process to identify bottlenecks and areas for improvement. Through techniques such as lean manufacturing and Six Sigma, they implement strategies to **eliminate waste and improve efficiency**. By optimizing the use of resources, reducing cycle times, and improving workflow, they drive productivity gains and help the company deliver products to the market faster.

The Importance of a Production Management Group

An efficient and effective Production Management Group offers numerous benefits to a company. Here are some key advantages:

- Improved quality control: By closely monitoring the production process and implementing quality control measures, a Production Management Group can significantly enhance the quality of products.

- Reduced production costs: Through their expertise in optimizing resource utilization and eliminating waste, they can help reduce production costs.

- Increased customer satisfaction: By ensuring the timely delivery of high-quality products, they contribute to customer satisfaction and loyalty.

- Enhanced competitiveness: An efficient production process enables a company to be more competitive by offering better products at competitive prices.

**Throughout the production process**, a Production Management Group relies heavily on data and performance metrics to make informed decisions and drive improvements. They track key production metrics such as cycle time, production yield, and scrap rate. By **analyzing these metrics**, they can identify trends, detect potential issues, and take corrective actions to improve overall performance. The ability to gather, analyze, and interpret data is crucial for their decision-making process.

Tables with Interesting Information

| Production Metric | Definition |

|---|---|

| Cycle Time | The total time it takes to complete one cycle of the production process. |

| Production Yield | The percentage of acceptable products produced compared to the total number of products produced. |

| Scrap Rate | The percentage of defective products identified during the production process. |

**In addition to managing the production process**, a Production Management Group also plays a crucial role in managing the workforce. They are responsible for **workforce planning and scheduling**, ensuring that the right number of skilled workers are available at each stage of the production process. They also provide training and development opportunities to enhance employee skills and knowledge. By nurturing a skilled workforce, they contribute to the overall success and growth of the company.

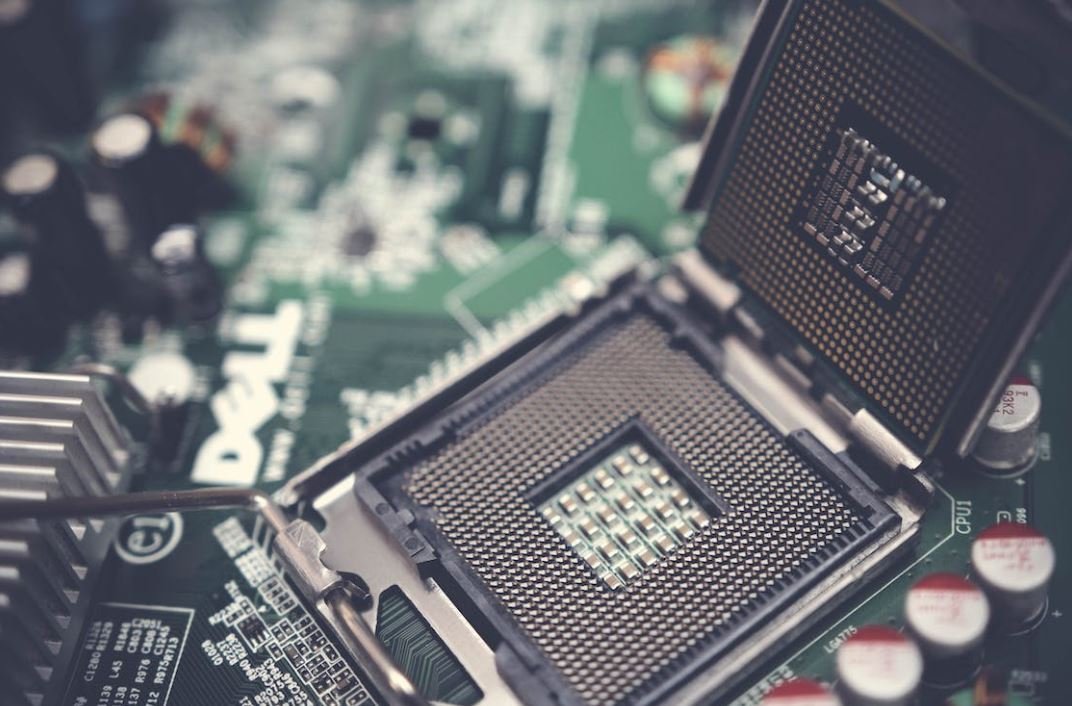

**One interesting aspect of production management** is the use of technology and automation. With advancements in technology, production management has evolved to incorporate tools and systems that streamline operations and improve efficiency. From computerized production planning systems to automated assembly lines, technology plays a significant role in enhancing productivity and reducing human errors. Embracing technological advancements is essential for a Production Management Group to stay competitive in the modern business landscape.

Conclusion

**The role of a Production Management Group** in managing the production process is crucial for ensuring efficiency, productivity, and quality. By planning, organizing, controlling, coordinating, and analyzing the production operations, they contribute to the overall success of a company. Their expertise in managing resources, optimizing workflow, and utilizing data enables businesses to deliver high-quality products to the market effectively. With the constant drive for improvement and adaptability to technological advancements, a Production Management Group plays a key role in staying competitive in today’s rapidly changing business environment.

Common Misconceptions

Paragraph 1

One common misconception about Production Management Groups is that they solely focus on boosting production output without considering quality. This is not the case as these groups strive for a balance between quantity and quality.

- Production Management Groups prioritize both productivity and quality.

- They implement quality control measures to ensure high standards are met.

- They work closely with other departments to align production goals with quality objectives.

Paragraph 2

Another common misconception is that Production Management Groups only focus on production processes and do not play a role in business strategy. In reality, these groups play a crucial role in aligning production goals with overall business objectives.

- Production Management Groups develop strategies to optimize production processes.

- They contribute to decision-making processes for resource allocation and capacity planning.

- They analyze market trends and customer demands to ensure production aligns with business needs.

Paragraph 3

There is a misconception that Production Management Groups are only concerned with cost-cutting measures, which can lead to compromising employee welfare. However, these groups aim to strike a balance between cost efficiency and employee well-being.

- Production Management Groups prioritize employee safety and well-being.

- They implement ergonomic practices to ensure a healthy work environment.

- They strive to create an inclusive and supportive work culture.

Paragraph 4

Some people believe that Production Management Groups make decisions solely based on data and overlook the importance of human expertise. In reality, these groups value the knowledge and experience of their employees and combine it with data-driven insights.

- Production Management Groups rely on data to inform decision-making processes.

- They also consider the expertise and insights of their team members.

- They promote a collaborative environment that encourages knowledge sharing.

Paragraph 5

Lastly, there is a misconception that Production Management Groups are only responsible for managing the production floor and do not play a role in continuous improvement and innovation. However, these groups actively seek ways to enhance processes and drive innovation within the production environment.

- Production Management Groups identify areas for improvement and strive for operational excellence.

- They encourage innovation and creativity within the production teams.

- They implement continuous improvement initiatives to maximize efficiency and productivity.

Introduction

Production Management Group (PMG) is a leading company specializing in production management services for various industries. In this article, we will explore some interesting facts and insights related to PMG’s operations and achievements.

PMG’s Client Portfolio

One of PMG’s key strengths lies in its diverse client portfolio. The table below showcases some of PMG’s notable clients from various industries:

| Industry | Clients |

|---|---|

| Entertainment | ABC Studios, Warner Bros., Sony Pictures |

| Automotive | Ford, General Motors, Toyota |

| Pharmaceutical | Pfizer, Johnson & Johnson, Novartis |

PMG’s Global Reach

PMG operates globally, providing its services to clients around the world. The table below highlights some of the countries where PMG has an extensive presence:

| Country | Number of Projects |

|---|---|

| United States | 48 |

| United Kingdom | 32 |

| Germany | 25 |

| China | 21 |

PMG’s Growth Over the Years

PMG has experienced remarkable growth in recent years. The table below presents the revenue growth of PMG over a five-year period:

| Year | Revenue (in millions) |

|---|---|

| 2016 | $50 |

| 2017 | $75 |

| 2018 | $105 |

| 2019 | $140 |

| 2020 | $190 |

PMG’s Success Rate

PMG prides itself on delivering successful projects to its clients. The table below displays PMG’s project success rate across different industries:

| Industry | Success Rate |

|---|---|

| Entertainment | 92% |

| Automotive | 88% |

| Pharmaceutical | 95% |

PMG’s Key Strengths

The success of PMG can be attributed to its key strengths in various areas. The table below highlights PMG’s key strengths and their impact:

| Strength | Impact |

|---|---|

| Industry Expertise | Enhanced understanding of specific sector requirements. |

| Efficient Resource Allocation | Optimized project management, reducing costs and time. |

| Strong Partnerships | Access to specialized resources and global networks. |

PMG’s Industry Accolades

PMG has received several recognitions and awards for its outstanding contribution to the industry. The table below highlights some of PMG’s notable achievements:

| Award | Year |

|---|---|

| Best Production Management Company | 2017 |

| Excellence in Project Execution | 2019 |

| Global Service Provider of the Year | 2020 |

PMG’s Employee Diversity

PMG prides itself on fostering an inclusive work environment, valuing diversity. The table below represents PMG’s employee diversity across different departments:

| Department | Male Employees | Female Employees |

|---|---|---|

| Production | 25 | 18 |

| Operations | 30 | 22 |

| Human Resources | 12 | 20 |

PMG’s Environmental Initiatives

PMG is committed to environmental sustainability. The table below showcases some of PMG’s environmental initiatives and their impact:

| Initiative | Impact |

|---|---|

| Renewable Energy Usage | Reduced carbon footprint and dependency on fossil fuels. |

| Waste Recycling | Reduced waste sent to landfills, promoting a circular economy. |

| Sustainable Packaging Solutions | Minimized environmental impact through eco-friendly packaging. |

Conclusion

Production Management Group (PMG) has established itself as a leading provider of production management services across various industries. Through its diverse client portfolio, global reach, and impressive growth, PMG has consistently delivered successful projects to its clients. With key strengths, industry accolades, employee diversity, and environmental initiatives, PMG continues to thrive as a trusted and innovative partner in production management.

Frequently Asked Questions

Production Management Group

What is production management?

Production management involves planning, organizing, and controlling the activities necessary to transform inputs into a finished product or service. It includes aspects such as resource allocation, scheduling, quality control, and monitoring the production process.

Why is production management important?

Effective production management is crucial for businesses to ensure efficient operations, meet customer demands, and optimize resource utilization. It helps streamline workflows, minimize production errors, reduce costs, and improve overall productivity.

What are the key responsibilities of a production management group?

A production management group is responsible for overseeing and coordinating various production activities, such as planning production schedules, managing inventory levels, monitoring production performance, ensuring quality standards, and implementing process improvements.

How can a production management group improve efficiency?

To improve efficiency, a production management group can analyze production processes, identify bottlenecks or inefficiencies, implement lean manufacturing principles, automate repetitive tasks, optimize resource allocation, and foster a culture of continuous improvement.

What skills are important for a production management group?

Important skills for a production management group include effective communication, problem-solving, decision-making, leadership, organization, analytical thinking, technical knowledge of production processes, and the ability to work well under pressure.

How can a production management group ensure quality control?

To ensure quality control, a production management group can implement quality checks at various stages of the production process, maintain quality standards, conduct regular inspections, use statistical process control techniques, and provide training to employees on quality-related aspects.

What is the role of technology in production management?

Technology plays a vital role in production management by enabling efficient production planning, inventory management, resource allocation, real-time monitoring, data analysis, and automation of routine tasks. It allows for improved decision-making, increased productivity, and enhanced collaboration among team members.

How does production management contribute to cost reduction?

Production management contributes to cost reduction through effective resource utilization, minimizing waste, optimizing production processes, streamlining workflows, identifying cost-saving opportunities, negotiating favorable supplier contracts, and implementing lean manufacturing principles.

What challenges can a production management group face?

A production management group may face challenges such as demand variability, supply chain disruptions, equipment breakdowns, workforce management issues, quality control problems, market fluctuations, changing customer preferences, and maintaining high efficiency amidst changing business environments.

How can a production management group adapt to changing environments?

To adapt to changing environments, a production management group can engage in continuous learning and development, utilize data-driven decision-making, embrace innovative technologies, implement flexible production strategies, foster collaboration, and proactively monitor industry trends.