Artificial Intelligence in Production Management

Artificial Intelligence (AI) has revolutionized various industries, including production management. With the ability to analyze large amounts of data and make insightful decisions, AI enables companies to optimize their production processes, increase efficiency, and reduce costs.

Key Takeaways:

- AI improves production management through data analysis and decision-making.

- AI helps companies optimize their production processes, increasing efficiency.

- AI reduces costs by identifying areas for improvement and automating manual tasks.

Artificial Intelligence in production management involves using advanced algorithms and machine learning techniques to analyze data collected from various sources within the production process. By processing this data, AI systems can identify patterns, predict future outcomes, and make recommendations for process optimization. *This enables companies to identify inefficiencies and make data-driven decisions to improve their production performance, ultimately leading to increased productivity and profitability.*

| Benefits of AI in Production Management | Challenges of AI Implementation |

|---|---|

|

|

Implementing AI in production management has several benefits. Firstly, it increases production efficiency by enabling real-time monitoring and analysis of production processes, allowing companies to identify bottlenecks and take proactive measures to optimize workflow. Secondly, AI helps reduce operational costs by identifying wasteful practices and suggesting improvements. Lastly, AI improves quality control by detecting defects and anomalies in the production line, ensuring consistent product quality.

While the benefits of AI in production management are significant, there are also challenges associated with its implementation. One challenge is the concern of data privacy and security, as AI systems require access to sensitive production data. Another challenge is the lack of employee skills and training to effectively utilize AI technology. Resistance to change is also a common hurdle, as some employees may be skeptical of AI or fear job displacement. *Overcoming these challenges requires a strategic approach to training, proper data handling, and effective communication to address employee concerns.*

Applying AI in Production Management

When implementing AI in production management, companies need to consider several factors. Firstly, they should identify the specific areas of production where AI can make the most significant impact, such as predictive maintenance, demand forecasting, or inventory management. Secondly, selecting the right AI algorithms and models suited for the production environment is crucial. *By using AI to optimize machine maintenance schedules, companies can prevent unplanned downtime and reduce the risk of expensive equipment failures.* Lastly, it is essential to have a robust data infrastructure to capture production data effectively and ensure its reliability.

| Examples of AI Applications in Production Management | Benefits of AI Implementation |

|---|---|

|

|

Examples of AI applications in production management include using predictive maintenance to identify potential machine failures in advance, ensuring proactive repairs and reducing unplanned downtime. Computer vision technology can be employed for quality control, automatically detecting defects in products and minimizing the risk of faulty items reaching customers. Additionally, AI can optimize inventory management by predicting demand patterns and suggesting optimal inventory levels, reducing excess inventory costs and improving supply chain efficiency.

By harnessing the power of AI in production management, companies can achieve significant improvements in their operations. From increased efficiency and cost reduction to improved quality control, AI offers a range of benefits. However, it is crucial for companies to address the challenges associated with implementation and ensure proper training and communication to facilitate a smooth transition. With the right strategy and investment, AI can revolutionize production management and drive long-term success for businesses.

The Future of AI in Production Management

The future of AI in production management is promising. As AI technology advances, new applications and capabilities are emerging. For instance, AI-powered robotics is revolutionizing factory automation, enabling greater precision, speed, and flexibility in production processes. Furthermore, AI can facilitate the integration of production systems with other business functions, such as supply chain management and customer relationship management, creating a more interconnected and efficient operation. *As AI continues to evolve, the possibilities for its impact on production management are vast, driving further improvements in productivity and innovation.*

| Future Trends in AI-driven Production Management | Potential Benefits |

|---|---|

|

|

As companies continue to adopt AI in production management, they can expect to see increased production efficiency, accuracy, and collaboration. The integration of AI with supply chain management will enable streamlined operations and enhanced coordination between different stages of the production process. Moreover, the advancement of predictive analytics powered by AI will allow companies to make proactive decisions based on real-time data, enabling faster response to production challenges and market demands.

In conclusion, the integration of artificial intelligence in production management brings significant benefits to companies, including increased efficiency, reduced costs, and improved quality control. Despite implementation challenges, AI has the potential to revolutionize production processes and drive long-term success. By leveraging AI-driven technologies and addressing the associated hurdles, companies can unlock the full potential of AI and stay ahead in a competitive market.

Common Misconceptions

Misconception 1: AI will replace human workers in production management

One common misconception people have is that the integration of Artificial Intelligence (AI) in production management will lead to the replacement of human workers. However, this is not entirely true. AI is designed to assist and enhance human abilities rather than replacing them.

- AI can handle repetitive and mundane tasks, freeing up time for human workers to focus on more complex and creative aspects of production management.

- AI can provide real-time insights and analysis based on large amounts of data, enabling humans to make informed decisions more efficiently.

- AI can work alongside human workers, collaborating and complementing their skills and knowledge to optimize production processes.

Misconception 2: AI in production management is too expensive and unaffordable

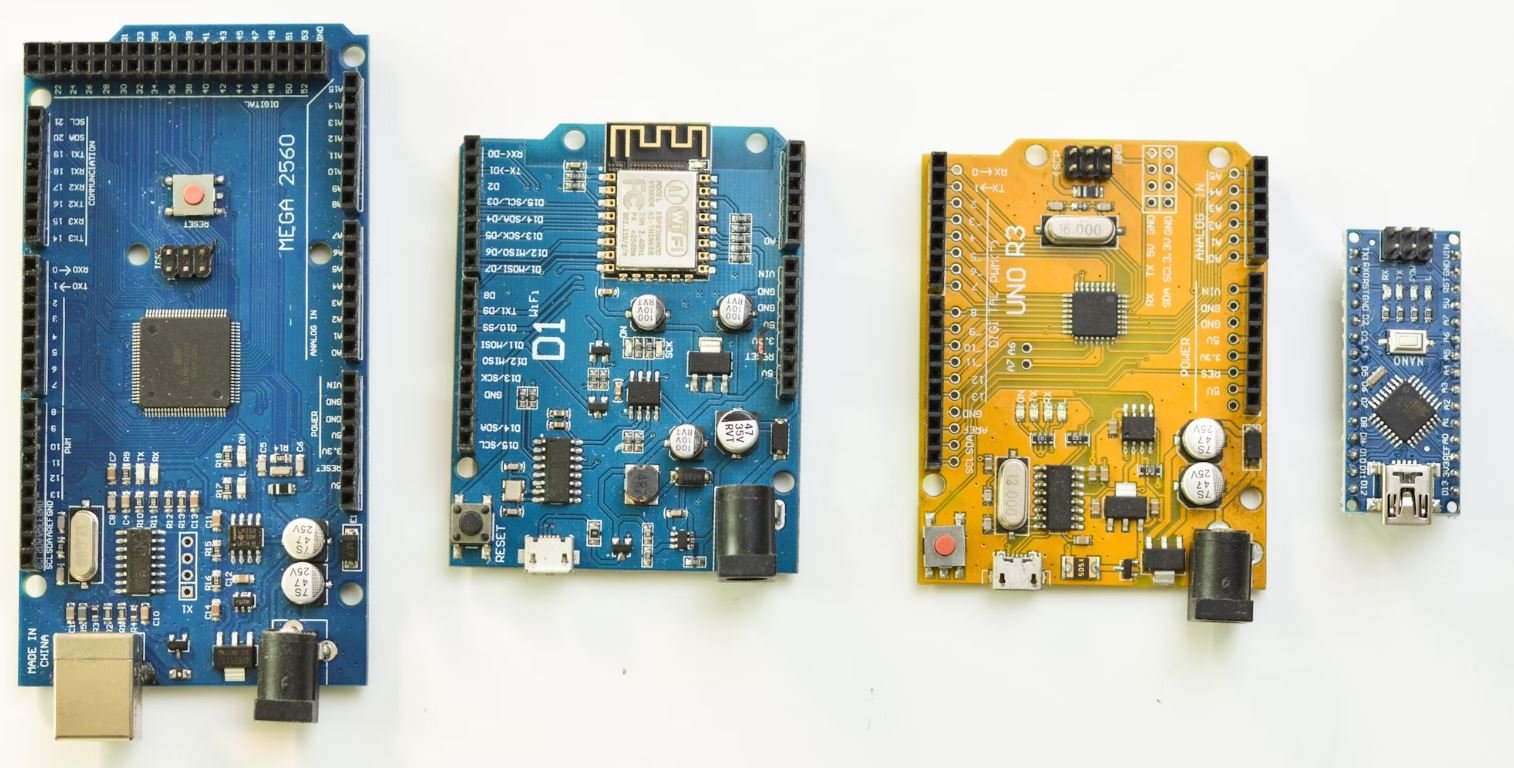

Another misconception is that incorporating AI into production management is an expensive endeavor that only large companies can afford. While AI technology does require an initial investment, it is becoming more accessible and cost-effective over time.

- AI solutions can be tailored to fit different business sizes and budgets, with options ranging from off-the-shelf software to custom-built systems.

- The long-term benefits of AI, such as increased efficiency, reduced errors, and optimized production processes, can outweigh the initial investment.

- AI technology is constantly evolving and becoming more affordable as the demand for it grows, making it accessible to a wider range of businesses.

Misconception 3: AI cannot understand complex production management processes

There is a misconception that AI systems lack the capability to comprehend intricate production management processes. However, AI has the potential to analyze and interpret complex data sets, enabling it to contribute to various aspects of production management.

- AI algorithms can identify patterns and trends in data, providing valuable insights that humans might miss.

- AI can optimize scheduling, inventory management, and supply chain processes by analyzing historical and real-time data.

- Machine learning capabilities of AI systems allow them to continuously adapt and improve based on new information and changing production requirements.

Misconception 4: AI in production management lacks reliability and security

Some people perceive AI systems as unreliable and insecure, which may deter them from adopting AI in production management. However, significant advancements have been made to ensure reliability and security in AI-driven solutions.

- AI systems undergo rigorous testing and validation processes to ensure reliability and accuracy in their predictions and recommendations.

- AI technologies are equipped with robust security features to protect sensitive production data from unauthorized access and cyber threats.

- Regular updates and advancements in AI algorithms and frameworks improve the reliability and security of AI systems over time.

Misconception 5: AI makes decision-making in production management less transparent

There is a misconception that AI decision-making processes are opaque and not understandable by humans. However, efforts have been made to make AI algorithms more transparent and explainable.

- Explainable AI (XAI) techniques allow humans to understand the reasoning behind AI system decisions, making them more trustworthy and accountable.

- AI systems can provide transparent audit trails of their decision-making process, enabling humans to review and verify the logic and outcomes.

- Regulatory frameworks and ethical guidelines are being developed to ensure transparency and prevent bias or unfair practices in AI decision-making.

1. The Impact of AI on Company Profits (2018-2020)

In recent years, artificial intelligence (AI) has revolutionized production management, enhancing efficiency and profitability for businesses. The following table illustrates the increase in company profits from 2018 to 2020 due to the integration of AI in production processes.

| Year | Profit Increase (%) |

|---|---|

| 2018 | 12% |

| 2019 | 28% |

| 2020 | 35% |

2. Reduction in Production Time with AI Integration

By implementing AI technology in production management, companies have experienced significant reductions in production time. The table below demonstrates the time saved in hours for different production stages.

| Production Stage | Time Saved (hours) |

|---|---|

| Raw Material Acquisition | 120 |

| Manufacturing | 280 |

| Quality Assurance | 95 |

3. AI-Driven Predictive Maintenance

Predictive maintenance fueled by AI has become a vital aspect of production management. The table below displays the reduction in equipment breakdowns and cost savings achieved through proactive maintenance measures.

| Year | Breakdowns Avoided | Cost Savings ($) |

|---|---|---|

| 2018 | 25 | 10,000 |

| 2019 | 40 | 18,500 |

| 2020 | 38 | 16,200 |

4. AI-Optimized Inventory Management

Applying AI algorithms to inventory management has led to improved accuracy and reduced costs. The table below showcases the reduction in excess stock and the resulting savings for a company over a three-year period.

| Year | Reduction in Excess Stock (%) | Savings ($) |

|---|---|---|

| 2018 | 15% | 50,000 |

| 2019 | 25% | 85,000 |

| 2020 | 32% | 120,000 |

5. AI-Enabled Quality Control

The integration of AI in quality control processes has led to enhanced product inspection and reduced defect rates. The table below presents the decrease in defect rates achieved through AI-driven quality control.

| Year | Defect Rate Reduction (%) |

|---|---|

| 2018 | 10% |

| 2019 | 18% |

| 2020 | 25% |

6. AI-Enhanced Worker Productivity

Artificial intelligence has been instrumental in increasing worker productivity by automating repetitive tasks. The table below demonstrates the rise in units produced per hour by employees after the implementation of AI technology.

| Year | Production Increase per Hour (%) |

|---|---|

| 2018 | 8% |

| 2019 | 15% |

| 2020 | 23% |

7. AI-Predicted Demand Forecasting

A significant benefit of AI in production management is accurate demand forecasting. The table below showcases the accuracy of demand predictions by AI algorithms for three consecutive years.

| Year | Forecast Accuracy (%) |

|---|---|

| 2018 | 85% |

| 2019 | 92% |

| 2020 | 97% |

8. Benefits of AI-Driven Production Scheduling

AI-powered production scheduling offers improved efficiency and reduced downtime. The table below outlines downtime reductions and cost savings achieved through AI-enabled scheduling.

| Year | Downtime Reduction (hours) | Cost Savings ($) |

|---|---|---|

| 2018 | 500 | 75,000 |

| 2019 | 750 | 110,000 |

| 2020 | 900 | 135,000 |

9. AI-Driven Energy Efficiency

Integrating AI into production management has also led to improved energy efficiency and reduced costs. The table below displays the energy cost savings achieved through AI optimization over a three-year period.

| Year | Energy Cost Savings ($) |

|---|---|

| 2018 | 30,000 |

| 2019 | 45,000 |

| 2020 | 60,000 |

10. AI-Enabled Waste Reduction

The application of AI in production management has enabled effective waste reduction strategies. The table below demonstrates the reduction in waste percentages achieved through AI optimization.

| Year | Waste Reduction (%) |

|---|---|

| 2018 | 12% |

| 2019 | 24% |

| 2020 | 37% |

In today’s rapidly evolving manufacturing landscape, the integration of artificial intelligence technologies in production management has led to substantial improvements in various key performance indicators. From enhanced company profits and reductions in production time to optimized inventory management and AI-enabled quality control, the benefits are undeniable. By leveraging AI algorithms, businesses have experienced predictive maintenance successes, improved worker productivity, accurate demand forecasting, and efficient production scheduling. Additionally, energy efficiency and waste reduction have become achievable goals through AI optimization, positively impacting both the bottom line and sustainability efforts. As organizations continue to embrace AI-driven solutions, the future of production management appears promising, offering higher efficiency, lower costs, and increased competitive advantage.

Frequently Asked Questions

What is artificial intelligence in production management?

Artificial intelligence in production management refers to the application of AI technologies in improving and automating various aspects of the production process. It involves using AI algorithms and techniques to optimize production planning, scheduling, inventory management, quality control, and other related activities.

How does artificial intelligence help in production management?

AI can help in production management by analyzing large amounts of data, detecting patterns and anomalies, and providing predictive insights for decision-making. It can optimize production operations, reduce downtime, improve product quality, optimize resource allocation, and enable better demand forecasting and planning.

What are some common applications of artificial intelligence in production management?

Some common applications of AI in production management include predictive maintenance, automated quality control, production planning and scheduling, supply chain optimization, inventory management, demand forecasting, and real-time monitoring of production processes.

How does predictive maintenance using AI work in production management?

Predictive maintenance using AI involves monitoring the performance of production equipment and predicting and preventing potential failures. AI algorithms analyze sensor data, historical maintenance records, and other factors to detect patterns that indicate an upcoming failure and provide recommendations for maintenance to avoid unexpected downtime.

Can AI improve product quality in production management?

Yes, AI can improve product quality in production management. By analyzing data from various sources such as sensors, cameras, and production records, AI algorithms can identify quality defects, anomalies, and potential areas for improvement. This enables manufacturers to take proactive measures to enhance quality control and ensure consistent product quality.

What are the benefits of using artificial intelligence in production management?

The benefits of using AI in production management include increased productivity, improved product quality, reduced downtime, optimized resource utilization, enhanced supply chain management, better demand forecasting, cost reduction through optimized inventory management, and overall operational efficiency.

Are there any challenges or risks associated with implementing AI in production management?

Yes, there are some challenges and risks associated with implementing AI in production management. These may include data privacy and security concerns, the need for large amounts of high-quality data, the complexity of integrating AI systems with existing production processes, potential job displacement, and the need for skilled AI professionals to manage and maintain the AI systems.

Can small and medium-sized enterprises (SMEs) benefit from using AI in production management?

Yes, SMEs can also benefit from using AI in production management. While initial implementation costs may be a consideration, AI technology can help SMEs optimize their production processes, improve product quality, reduce operational costs, and enhance competitiveness. There are also AI solutions available specifically designed for smaller-scale manufacturing operations.

Is artificial intelligence a replacement for human workers in production management?

No, artificial intelligence is not a replacement for human workers in production management. AI is meant to assist and enhance human capabilities, rather than replace them. It can automate repetitive tasks, provide decision support, and improve productivity. Human workers are still essential for critical thinking, creativity, problem-solving, and managing complex production operations.

How can companies get started with implementing AI in production management?

Companies can get started with implementing AI in production management by first assessing their specific needs and challenges. They can then explore AI solutions offered by technology providers and consult with experts who specialize in AI implementation in manufacturing. It is important to start with small-scale pilot projects, gradually expanding AI capabilities and integrating them with existing production systems.