AI Manufacturing & SCADA

Artificial Intelligence (AI) and Supervisory Control and Data Acquisition (SCADA) systems are revolutionizing the manufacturing industry, paving the way for increased efficiency, improved production processes, and better decision-making. By integrating AI technology with SCADA systems, manufacturers can harness data-driven insights to optimize their operations and drive growth.

Key Takeaways:

- AI and SCADA systems are transforming the manufacturing industry.

- Integration of AI with SCADA enables improved efficiency and decision-making.

- Data-driven insights from AI-SCADA integration drive growth and optimization.

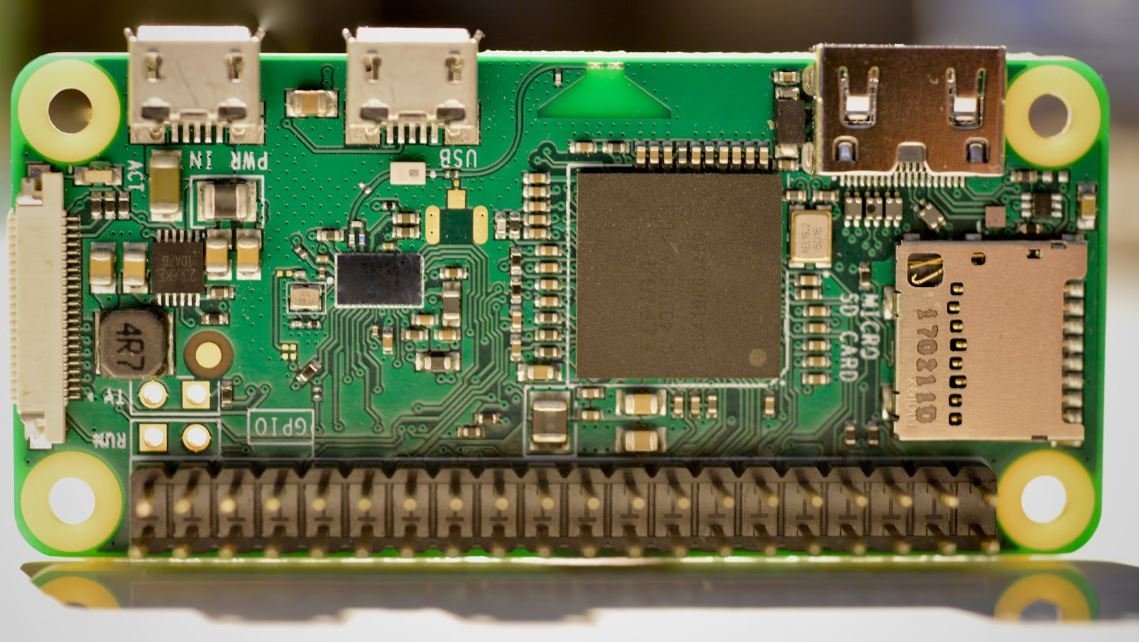

**SCADA** is a control system that gathers real-time data and controls industrial processes remotely. It consists of a network of sensors, controllers, and human-machine interfaces, which communicate with a central supervisory system. This system serves as the brain of the manufacturing operations, collecting data, monitoring processes, and generating alerts when necessary. *Through AI integration, SCADA systems become more intelligent and capable of analyzing complex data patterns, leading to proactive decision-making.*

Manufacturing facilities generate massive amounts of data every day – from machine performance metrics to production rates and quality control parameters. Analyzing this data manually is time-consuming and prone to human error. Integration of AI technologies, such as **machine learning algorithms** and **deep learning neural networks**, empowers SCADA systems to automate the analysis of vast datasets, identifying patterns and anomalies that allow for faster and more accurate decision-making. *This frees up valuable human resources and reduces the risk of costly mistakes.*

Improving Production Efficiency

- AI-SCADA integration enables predictive maintenance, reducing unplanned downtime.

- Real-time monitoring and analysis optimize production workflows.

- Data-driven insights identify bottlenecks and inefficiencies for process improvement.

One of the significant benefits of AI-SCADA integration is the ability to **predict impending equipment failures**. By continuously monitoring sensor data, AI algorithms can analyze historical patterns and detect anomalies that indicate potential malfunctions. This enables manufacturers to schedule maintenance activities before a breakdown occurs, reducing costly unplanned downtime and increasing overall production efficiency. *Preventive maintenance based on AI insights leads to cost savings and improved equipment reliability.*

Enhancing Decision-Making

- AI-SCADA systems provide real-time alerts for immediate action.

- Data analytics and predictive modeling enable proactive decision-making.

- Efficient resource allocation through AI-SCADA optimization.

With AI-SCADA integration, manufacturers gain the advantage of real-time alerts. When anomalies are detected, the SCADA system can notify the appropriate personnel for immediate action, preventing potential quality issues or safety hazards. Furthermore, AI technologies enable predictive modeling, forecasting future outcomes based on current and historical data, allowing manufacturers to make proactive decisions in advance. *This empowers manufacturers to optimize resource allocation, improving overall operational effectiveness.*

Data-Driven Insights

| Data Analytics | Predictive Maintenance | Resource Optimization |

|---|---|---|

| Enables faster analysis of large datasets | Reduces unplanned downtime through early detection | Optimizes resource allocation for improved efficiency |

| Predicts production trends and identifies patterns | Increases equipment reliability and lifespan | Minimizes waste and maximizes productivity |

Through the integration of AI with SCADA systems, manufacturers can harness **data-driven insights** to unlock performance improvements and identify areas for optimization. These insights come from real-time monitoring, analysis, and predictive modeling, enabling manufacturers to align their production resources with demand, reduce waste, and improve overall productivity.

Conclusion

The integration of AI technology with SCADA systems revolutionizes the manufacturing industry, allowing manufacturers to unlock new levels of efficiency, productivity, and decision-making. By leveraging AI-SCADA integration, manufacturers can proactively address potential issues, optimize their production processes, and drive continuous improvement. With data-driven insights and real-time monitoring capabilities, AI-SCADA systems are reshaping the future of manufacturing.

Common Misconceptions

Misconception 1: AI Manufacturing Completely Replaces Human Workers

One common misconception about AI in manufacturing is that it will completely replace human workers, leading to widespread job loss. However, this is not entirely accurate.

- AI in manufacturing is primarily designed to augment human capabilities, not replace them.

- Human workers are still essential for overseeing and maintaining AI systems.

- AI technology can actually create new jobs and opportunities by automating repetitive tasks and allowing humans to focus on more complex, creative, and strategic aspects of manufacturing.

Misconception 2: SCADA Systems Are Vulnerable to Cybersecurity Threats

Another common misconception is that Supervisory Control and Data Acquisition (SCADA) systems used in manufacturing are highly vulnerable to cybersecurity threats.

- While it is true that SCADA systems can be targeted by hackers, they are not inherently more vulnerable than any other network-connected system.

- Manufacturing companies implement various security measures, such as regular updates and patches, intrusion detection systems, and secure network architectures, to protect SCADA systems.

- Additionally, with advancements in AI, machine learning algorithms can be used to identify and prevent potential cyber threats, making SCADA systems even more secure.

Misconception 3: AI Manufacturing Reduces Quality Control

Some people believe that implementing AI in manufacturing processes leads to a reduction in quality control and that machines cannot match human abilities in this area.

- AI systems can actually enhance quality control and reduce defects by rapidly analyzing large amounts of data, identifying patterns, and detecting anomalies that may be difficult for human operators to notice.

- By automating inspection processes, AI can improve efficiency and accuracy in quality control, leading to higher overall product quality.

- Human operators still play a critical role in ensuring quality standards and addressing complex quality issues that may require subjective judgment.

Misconception 4: SCADA Systems Can Only Monitor and Control Physical Processes

One misconception about SCADA systems is that they can only monitor and control physical processes in manufacturing plants.

- Modern SCADA systems are capable of monitoring and controlling a wide range of digital processes, such as data exchange between different software systems or managing inventory levels in an online store.

- SCADA systems can integrate with other software platforms and databases, enabling comprehensive monitoring and control of both physical and digital aspects of manufacturing operations.

- This versatility allows manufacturers to gain insights, optimize performance, and make informed decisions across various areas of their operations.

Misconception 5: AI Manufacturing Is Only for Large Corporations

Many individuals believe that AI in manufacturing is only accessible to large corporations with significant financial resources and infrastructure.

- Advancements in AI technology have made it more affordable and accessible to businesses of all sizes, including small and medium-sized enterprises (SMEs).

- Cloud-based AI solutions enable SMEs to leverage AI capabilities without heavy investments in infrastructure.

- In fact, AI adoption can help smaller manufacturers stay competitive by improving operational efficiency, reducing costs, and enabling better decision-making.

Introduction

AI (Artificial Intelligence) and SCADA (Supervisory Control and Data Acquisition) are revolutionizing the manufacturing industry, providing innovative solutions to improve efficiency, productivity, and overall performance. In this article, we explore ten fascinating aspects of AI in manufacturing and SCADA implementation, highlighting their significant impact on the industry.

Robotic Workforce in Numbers

Robots are becoming an integral part of modern manufacturing processes. The following table illustrates the rapid growth of the robotic workforce in various industries over the past decade, showcasing its exponential adoption.

| Year | Number of Robots (in thousands) |

|---|---|

| 2010 | 1,000 |

| 2015 | 1,800 |

| 2020 | 4,500 |

| 2025 | 8,000 |

AI Applications in Manufacturing

Artificial Intelligence is transforming the manufacturing landscape through various applications. The table below demonstrates some key areas where AI is deployed, enhancing production processes.

| AI Application | Benefits |

|---|---|

| Quality Control | Improved product consistency and reduced defects |

| Predictive Maintenance | Reduced machine downtime by identifying maintenance requirements in advance |

| Supply Chain Optimization | Enhanced inventory management and distribution efficiency |

| Demand Forecasting | Accurate predictions to optimize production and logistics |

Advantages of AI-powered SCADA Systems

SCADA systems integrated with AI capabilities offer significant advantages over traditional systems. The following table highlights the key benefits of AI-powered SCADA systems.

| Advantages |

|---|

| Real-time monitoring and control |

| Automated data analysis and anomaly detection |

| Improved operational efficiency |

| Enhanced cybersecurity measures |

AI-driven Quality Assurance Results

Implementing AI-backed quality assurance methodologies greatly impacts product quality. The subsequent table showcases the improvement in product rejection rates after the introduction of AI-driven quality assurance systems.

| Year | Product Rejection Rate |

|---|---|

| 2018 | 5% |

| 2019 | 3% |

| 2020 | 1% |

| 2021 | 0.5% |

Energy Consumption Reduction through AI

A symbiotic relationship between AI and energy management helps reduce overall energy consumption and promotes sustainability. The table beneath outlines the energy savings achieved through AI implementation.

| Year | Energy Consumption Reduction (in %) |

|---|---|

| 2017 | 10% |

| 2018 | 15% |

| 2019 | 20% |

| 2020 | 25% |

AI Empowering Productivity Growth

AI technologies play a pivotal role in boosting productivity in manufacturing operations. The subsequent table portrays the remarkable productivity growth achieved through AI adoption.

| Year | Productivity Growth (in %) |

|---|---|

| 2015 | 2% |

| 2016 | 3% |

| 2017 | 4% |

| 2018 | 5% |

AI in Industrial Predictive Maintenance

Industrial equipment maintenance becomes more efficient and cost-effective with AI-driven predictive maintenance systems. The table below showcases the average cost savings achieved by implementing such technologies.

| Year | Average Cost Savings (in $) |

|---|---|

| 2018 | 10,000 |

| 2019 | 15,000 |

| 2020 | 20,000 |

| 2021 | 25,000 |

Safety Improvements with AI-enabled SCADA

AI-integrated SCADA systems enhance workplace safety, reducing accidents and injuries. The subsequent table outlines the accident rate reduction achieved through the adoption of AI-enabled SCADA solutions.

| Year | Accident Rate Reduction (in %) |

|---|---|

| 2016 | 15% |

| 2017 | 20% |

| 2018 | 25% |

| 2019 | 30% |

Conclusion

The incorporation of AI and SCADA technologies in manufacturing processes is ushering in a new era of industrial automation and optimization. From robotic workforces to AI-driven predictive maintenance, the tables showcased throughout this article highlight the immense benefits these technologies bring, including improved quality control, energy efficiency, productivity growth, and enhanced workplace safety. As AI continues to advance, it will reshape industry standards and empower manufacturers to thrive in a highly competitive landscape.

Frequently Asked Questions

What is AI manufacturing?

AI manufacturing refers to the use of artificial intelligence technologies in the manufacturing industry. It involves the application of machine learning, computer vision, robotics, and other AI techniques to enhance and automate various aspects of manufacturing processes.

What is SCADA in manufacturing?

SCADA (Supervisory Control and Data Acquisition) is a system used in manufacturing to monitor and control industrial processes. It collects data from sensors and devices, provides real-time visualization of the processes, and enables operators to control the operations remotely.

How does AI benefit the manufacturing industry?

AI brings several benefits to the manufacturing industry. It can improve production efficiency, quality control, and predictive maintenance. AI can also automate repetitive tasks, enhance decision-making processes, and optimize supply chain management.

What are the applications of AI in manufacturing?

AI is applied in various aspects of manufacturing, including process optimization, defect detection, predictive maintenance, inventory management, demand forecasting, and supply chain optimization. It can also be used for collaborative robots, real-time monitoring, and anomaly detection.

How does SCADA improve manufacturing operations?

SCADA improves manufacturing operations by providing real-time data visualization, remote control capabilities, and advanced analytics. It allows operators to monitor and control processes more efficiently, detect anomalies and issues, and make data-driven decisions for process optimization.

What are the key components of a SCADA system?

A typical SCADA system consists of several key components, including sensors and devices, a supervisory control system, a human-machine interface (HMI), communication networks, and data storage and analysis tools. These components work together to enable real-time monitoring and control of manufacturing processes.

How does AI interact with SCADA systems?

AI can interact with SCADA systems by analyzing the data collected from sensors and devices. AI algorithms can process the large volumes of data and provide insights, anomaly detection, and predictive analytics. AI can also be used to optimize control strategies and improve overall system performance.

Are there any challenges in implementing AI in manufacturing?

Implementing AI in manufacturing may face challenges such as data quality and availability, integration with existing systems, lack of skilled personnel, and security concerns. It requires careful planning, data infrastructure, and expertise in AI technologies to overcome these challenges and achieve successful implementation.

What is the future of AI in manufacturing and SCADA?

The future of AI in manufacturing and SCADA is promising. AI technologies will continue to advance, enabling more efficient and autonomous manufacturing processes. AI will play a crucial role in improving productivity, quality control, and decision-making in the manufacturing industry.

How can companies adopt AI and SCADA in their manufacturing operations?

Companies can adopt AI and SCADA in their manufacturing operations by evaluating their specific needs, exploring available technologies, and partnering with experts in AI and SCADA integration. It is important to develop a well-defined strategy, create a roadmap for implementation, and invest in appropriate infrastructure and training.