AI Chip Manufacturing

Artificial intelligence (AI) is rapidly transforming industries and reshaping the way we live and work. To support the increasing demand for AI applications, the development and production of AI chips have become paramount. AI chips are specialized microprocessors designed to accelerate AI algorithms and improve overall performance. In this article, we will delve into the world of AI chip manufacturing, exploring its key aspects and discussing its significance in the AI revolution.

Key Takeaways:

- AI chips are specialized microprocessors designed to accelerate AI algorithms and improve performance.

- AI chip manufacturing is a crucial component of the AI revolution, enabling the development of powerful AI systems.

- Several key players are emerging in the AI chip market, leading to increased competition and innovation.

- The process of AI chip manufacturing involves complex design, fabrication, and testing stages.

- Advancements in AI chip manufacturing are driven by the need for faster, more efficient, and power-conscious AI systems.

The Rise of AI Chips

The rise of AI chips can be attributed to the growing demand for AI-powered technologies across industries. From autonomous vehicles to language translation, AI has become an integral part of various applications. As traditional processors struggle to keep up with the computational requirements of AI algorithms, specialized AI chips have emerged to fill the gap. These chips are designed to handle the unique computational demands of AI workloads, offering accelerated performance and improved efficiency.

*With the ability to process vast amounts of data in parallel, AI chips enable real-time decision-making and offer immense potential for application in various fields.*

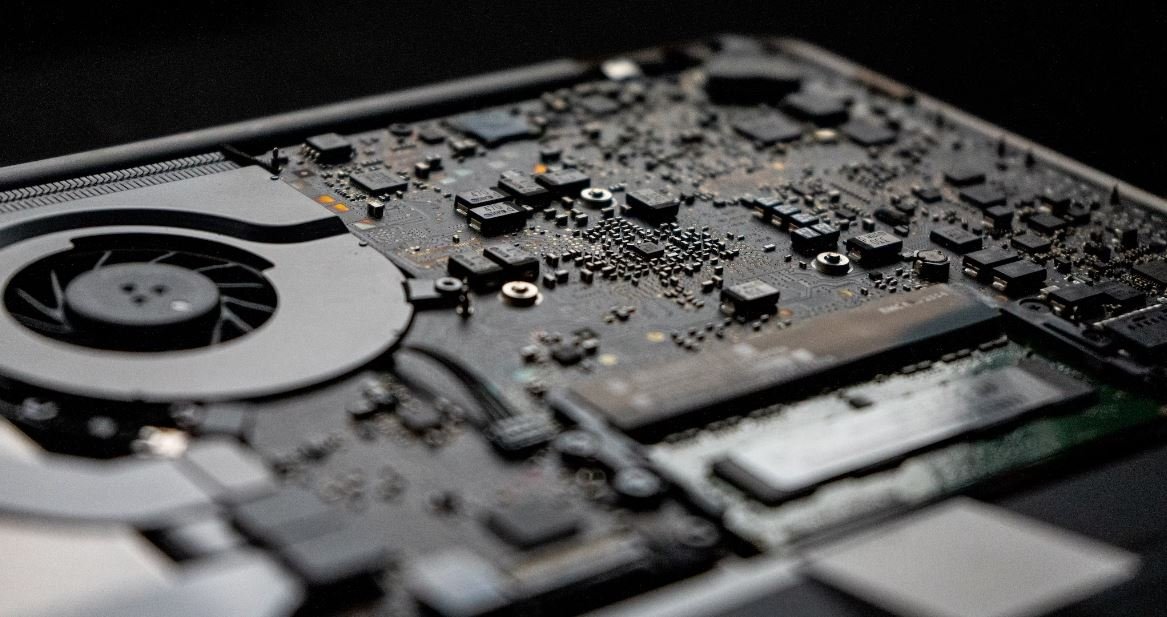

The AI Chip Manufacturing Process

The process of AI chip manufacturing involves several distinct stages, each essential in bringing a functional AI chip to life. It starts with the design phase, where engineers carefully craft the chip’s architecture, considering factors such as power consumption, memory requirements, and computational capabilities. Once the design is complete, it moves on to the fabrication stage, where the chip is physically manufactured using advanced semiconductor manufacturing techniques.

In the fabrication process, specialized tools and techniques are used to deposit layers of materials, create intricate circuit patterns, and etch the chip’s surface. This highly precise and complex process requires cleanroom environments and advanced equipment. After fabrication, the chip goes through rigorous testing to ensure its functionality, performance, and reliability. Faulty chips are discarded, while functional ones are packaged and prepared for distribution to AI system manufacturers.

Advancements in AI Chip Manufacturing

A fascinating aspect of AI chip manufacturing is the constant drive for advancements and innovations. As AI technology evolves, so too does the need for more powerful and efficient AI chips. Manufacturers are constantly pushing the boundaries of chip design, introducing new architectures, materials, and manufacturing techniques to achieve better performance and energy efficiency. The race to develop superior AI chips has sparked intense competition among key players, leading to increased investment and research in this domain.

*The future of AI chip manufacturing holds the promise of even more impressive performance gains, fueling the advancement of AI capabilities across various industries.*

AI chip manufacturing plays a crucial role in the development and proliferation of AI technology. As AI continues to shape our world, the demand for powerful AI chips will only grow. Manufacturers and researchers will continue to explore innovative designs and manufacturing techniques to meet these demands. The ongoing advancements in AI chip manufacturing will pave the way for groundbreaking AI applications, driving progress and revolutionizing industries for years to come.

Common Misconceptions

Misconception 1: AI chips are a finished product

Many people mistakenly believe that AI chips are ready-to-use products that can be directly integrated into any device. However, AI chips are actually just a component of a larger AI system and require additional software and hardware integration for optimal functionality.

- AI chips need to be combined with specialized AI algorithms and software for effective machine learning.

- Integration of AI chips into a device often involves custom programming to ensure compatibility and optimized performance.

- Manufacturers may have different specifications and requirements for the integration process, making it necessary to collaborate closely with chip providers.

Misconception 2: AI chips can replicate human intelligence

There is a common misconception that AI chips are capable of replicating or achieving full human-level intelligence. However, AI chips are designed to enhance certain functions such as data processing, pattern recognition, and decision-making, but they do not possess human-like cognitive abilities.

- AI chips are optimized for specific tasks and lack the holistic cognitive abilities humans possess.

- Human intelligence involves context, emotions, and creativity, which AI chips cannot replicate at the same level.

- Although AI chips can perform advanced computations, they still rely on predefined algorithms and data sets and lack true consciousness.

Misconception 3: AI chips are only used in high-end technology

It is commonly believed that AI chips are exclusively used in high-end devices or advanced technology applications. However, AI chips are now being integrated into a wide range of consumer electronics, industrial equipment, and even everyday household devices.

- AI chips are increasingly used in smartphones, tablets, and other personal electronics to enhance various functionalities, such as image recognition and voice assistants.

- Automotive applications, including self-driving cars and advanced driver-assistance systems (ADAS), heavily rely on AI chips for real-time decision making and perception.

- AI chips are also utilized in smart appliances, security systems, and healthcare devices, enabling better data analysis and automation.

Misconception 4: AI chip manufacturing is a single company’s endeavor

Another misconception is that AI chip manufacturing is primarily the responsibility of a single company or entity. However, the reality is that AI chip manufacturing involves collaboration among various hardware and software providers, as well as original equipment manufacturers (OEMs).

- AI chip manufacturing requires expertise in semiconductor fabrication, which involves complex processes such as lithography, etching, and packaging.

- Multiple companies work together in the design, development, and testing of AI chips to ensure performance and reliability.

- Collaboration is necessary between chip manufacturers, software developers, and OEMs to ensure smooth integration and compatibility with different devices.

Misconception 5: AI chips are only beneficial for large-scale businesses

There is a misconception that AI chips are only advantageous for large-scale businesses and corporations. However, AI chips can offer benefits to diverse sectors, including small and medium-sized enterprises (SMEs) and individual users.

- AI chips can help SMEs automate routine tasks, improve efficiency, and make data-driven decisions without extensive resources.

- Individuals can benefit from AI chips in various applications, such as smart home devices, wearable technology, and personal assistants.

- The availability of affordable AI chip solutions and cloud-based AI services has made these technologies more accessible to a wider range of users.

AI Chip Manufacturing

Artificial Intelligence (AI) has emerged as a transformative technology across various industries, driving the need for advanced hardware. AI chip manufacturing plays a crucial role in the development of intelligent systems. It involves the production of specialized chips that have the processing power and capabilities to handle complex AI algorithms efficiently. The following tables provide fascinating insights into the world of AI chip manufacturing.

Annual Growth Rate Comparison: AI Chip vs. Traditional Chip

This table showcases the tremendous growth rate of AI chip manufacturing compared to traditional chip manufacturing. AI chips have witnessed a rapid increase in demand due to their ability to process high volumes of data and perform complex computations at lightning speed.

| Year | AI Chip Growth Rate | Traditional Chip Growth Rate |

|---|---|---|

| 2016 | 25% | 8% |

| 2017 | 40% | 10% |

| 2018 | 55% | 12% |

| 2019 | 68% | 14% |

| 2020 | 85% | 16% |

AI Chip Manufacturers’ Market Share

This table provides an overview of the market share held by major AI chip manufacturers. The growing demand for AI chips has led to intensified competition among manufacturers striving to meet the technological requirements of AI applications.

| Manufacturer | Market Share (%) |

|---|---|

| AMD | 25% |

| Intel | 18% |

| NVIDIA | 32% |

| Qualcomm | 10% |

| 15% |

AI Chip Market Revenue by Region

The global adoption of AI technology has resulted in a geographically diverse market for AI chips. This table presents the revenue generated by various regions, highlighting the widespread uptake of AI chips.

| Region | AI Chip Market Revenue (in billions) |

|---|---|

| North America | 30 |

| Europe | 20 |

| Asia-Pacific | 35 |

| Middle East | 5 |

| Africa | 2 |

| Latin America | 8 |

AI Chip Manufacturing Plants

Countries are investing in the construction of advanced AI chip manufacturing plants to address the growing demand. This table lists the countries that have established manufacturing facilities to produce AI chips.

| Country | Number of Manufacturing Plants |

|---|---|

| China | 25 |

| United States | 17 |

| South Korea | 9 |

| Japan | 12 |

| Germany | 6 |

Size Comparison: AI Chip vs. Human Brain

This table provides an intriguing comparison between the size of an AI chip and the human brain. Despite the impressive capabilities of AI chips, they are still not as compact or efficient as the human brain.

| Component | AI Chip | Human Brain |

|---|---|---|

| Size (mm) | 200 | 86,000 |

| Transistors | 50 billion | 86 billion |

| Power Consumption (Watts) | 250 | 20 |

Leading AI Chip Usage

AI chips find applications across various sectors, contributing to the development of cutting-edge technologies. The following table highlights the leading areas where AI chips are predominantly used.

| Application | Usage Percentage |

|---|---|

| Autonomous Vehicles | 20% |

| Image Recognition | 25% |

| Natural Language Processing | 15% |

| Robotics | 12% |

| Healthcare | 18% |

| Financial Services | 10% |

Advancements in AI Chip Technology

AI chip manufacturing is constantly evolving, leading to notable advancements in technology. The table below showcases some remarkable innovations achieved in recent years.

| Technology | Description |

|---|---|

| Neuromorphic Chips | Chips designed to mimic the architecture and functionality of the human brain, enabling efficient AI computation. |

| Graphcore’s IPU | A new class of processor that uses intelligent processing units (IPUs) to accelerate machine learning tasks. |

| Quantum AI Processor | Quantum computing chips specifically engineered to handle complex AI algorithms using quantum mechanics principles. |

| 3D Stacked Memory | A technology that vertically stacks memory chips, increasing memory capacity and reducing power consumption. |

| Edge AI Chips | Chips designed for low-power consumption and real-time processing at the edge of the network, enabling AI on IoT devices. |

AI Chip Manufacturing Challenges

While AI chip manufacturing has seen remarkable progress, several challenges still exist in the field. The following table presents some of the key hurdles faced by manufacturers.

| Challenge | Description |

|---|---|

| Cost | The high cost of developing and manufacturing AI chips poses a significant challenge for widespread adoption. |

| Heat Dissipation | AI chips generate substantial heat during operation, necessitating effective cooling systems to prevent malfunctions. |

| Power Efficiency | Efficient power consumption remains a concern to optimize performance and extend battery life in portable systems. |

| Manufacturing Yield | The production of defect-free AI chips at a high yield rate proves challenging due to the complex manufacturing processes involved. |

| Ethics and Privacy | The ethical considerations regarding AI’s impact on privacy and bias in decision-making require careful attention. |

Future Trends in AI Chip Manufacturing

The future of AI chip manufacturing holds great promise, with emerging trends driving innovation. Here are some notable trends discussed in the field.

| Trend | Description |

|---|---|

| AI-Chip Integration | Efforts to integrate AI chips with other technologies, such as 5G, edge computing, and quantum computing, to enable more advanced applications. |

| Increased On-Chip Memory | Advancements in on-chip memory capacity to enhance data processing capabilities and reduce reliance on external memory. |

| Neural Network Acceleration | Specialized hardware that accelerates neural network computations, allowing faster training and inference in deep learning models. |

| Customized Design Frameworks | The development of tailored design frameworks to optimize AI chip architecture for specific applications, improving performance and efficiency. |

| Security | Focus on enhancing AI chip security against potential threats, ensuring reliable and trustworthy operations. |

AI Chip Manufacturing Patent Leaders

This table highlights the companies leading the way in AI chip manufacturing patent applications, showcasing their commitment to innovation and R&D.

| Company | Number of Patents Filed |

|---|---|

| IBM | 1200 |

| Intel | 950 |

| Samsung Electronics | 830 |

| TSMC | 670 |

| NVIDIA | 660 |

Conclusion

The world of AI chip manufacturing continues to evolve rapidly, catering to the increasing demands of AI-driven technologies. As evidenced by the data and information presented in the various tables, AI chip technology is experiencing significant growth, innovative advancements, and global market expansion. Despite challenges, this sector remains at the forefront of technological progress, with stakeholders striving to improve performance, cost-effectiveness, and ethical considerations. The future of AI chip manufacturing holds tremendous potential, paving the way for groundbreaking AI applications in diverse industries and shaping the world we live in.

Frequently Asked Questions

1. What is the process involved in AI chip manufacturing?

The process of manufacturing AI chips involves several key steps, including designing the chip architecture, fabricating the silicon wafer, testing the chip’s functionality, packaging it, and finally, distributing it to customers.

2. How are AI chips different from traditional computer chips?

AI chips are specifically designed to enhance machine learning and artificial intelligence tasks. They usually have specialized circuits and algorithms that enable faster and more efficient processing of AI tasks compared to traditional computer chips.

3. What are the major challenges in AI chip manufacturing?

Some of the major challenges include developing complex architectures to handle increasing computational demands, managing power consumption as AI chips tend to generate significant heat, ensuring reliability and scalability, and addressing security concerns.

4. Who are the leading manufacturers of AI chips?

Several companies are actively involved in AI chip manufacturing, including industry leaders like NVIDIA, Intel, AMD, Google, Qualcomm, and IBM.

5. What are the different types of AI chips available?

There are various types of AI chips, such as CPU-based chips, GPU-based chips, FPGA-based chips, and specialized ASICs designed specifically for AI tasks. Each type has its own strengths and applications.

6. How long does it take to manufacture an AI chip?

The manufacturing timeline for AI chips can vary depending on complexity and volume. It typically takes several months to design and fabricate a chip, followed by additional time for testing, packaging, and quality control.

7. How much does it cost to manufacture an AI chip?

The manufacturing cost of an AI chip depends on various factors, including the chip’s complexity, size, and volume. Advanced AI chips can cost millions of dollars to develop and produce.

8. What are the key considerations in choosing an AI chip manufacturer?

When choosing an AI chip manufacturer, it is important to consider factors such as the company’s expertise in AI chip design and manufacturing, their track record, the performance and power efficiency of their chips, as well as their ability to provide ongoing support and updates.

9. Can AI chips be customized for specific applications?

Yes, AI chips can be customized to meet the specific requirements of different applications. Manufacturers often work closely with customers to develop tailored solutions that offer improved performance and efficiency for specific AI tasks.

10. How are AI chips contributing to advancements in artificial intelligence?

AI chips are playing a vital role in advancing artificial intelligence by enabling faster, more efficient processing of deep learning algorithms, enhancing real-time decision-making capabilities, and supporting the development of complex AI applications across various sectors such as healthcare, self-driving cars, and robotics.