AI-Based Manufacturing

The integration of artificial intelligence (AI) in manufacturing processes has revolutionized the industry, redefining efficiency and productivity. AI-powered machines and systems are capable of performing complex tasks with increased accuracy and speed, paving the way for advanced manufacturing techniques.

Key Takeaways:

- AI enables automation and optimization of manufacturing processes.

- AI-based manufacturing improves product quality and reduces defects.

- AI enhances predictive maintenance and minimizes production downtime.

- AI-driven analytics provide valuable insights for process optimization.

In AI-based manufacturing, **machines are equipped with sophisticated algorithms** that allow them to learn from previous data and make intelligent decisions on their own. This autonomous decision-making process reduces human intervention and enhances the efficiency of manufacturing plants. For instance, *robots can adjust their movements in real-time, optimizing throughput and reducing errors*.

One of the significant advantages of AI-based manufacturing is the **improvement in product quality**. AI-enabled systems can identify defects and inconsistencies more accurately than humans, resulting in products with higher standards of quality. Moreover, *the continuous learning capabilities of AI enable adaptive control, ensuring precise and consistent manufacturing processes*.

Use of AI in Manufacturing:

AI is applied across various stages of the manufacturing process, enabling optimization and greater efficiency. Let’s explore some of the key areas where AI-based systems are making a significant impact:

1. Predictive Maintenance:

AI delivers **predictive maintenance** capabilities by monitoring equipment performance and analyzing historical data. By identifying early signs of machinery failures, manufacturers can perform maintenance proactively and prevent unplanned downtime. This proactive approach eliminates costly interruptions in production and maximizes equipment utilization.

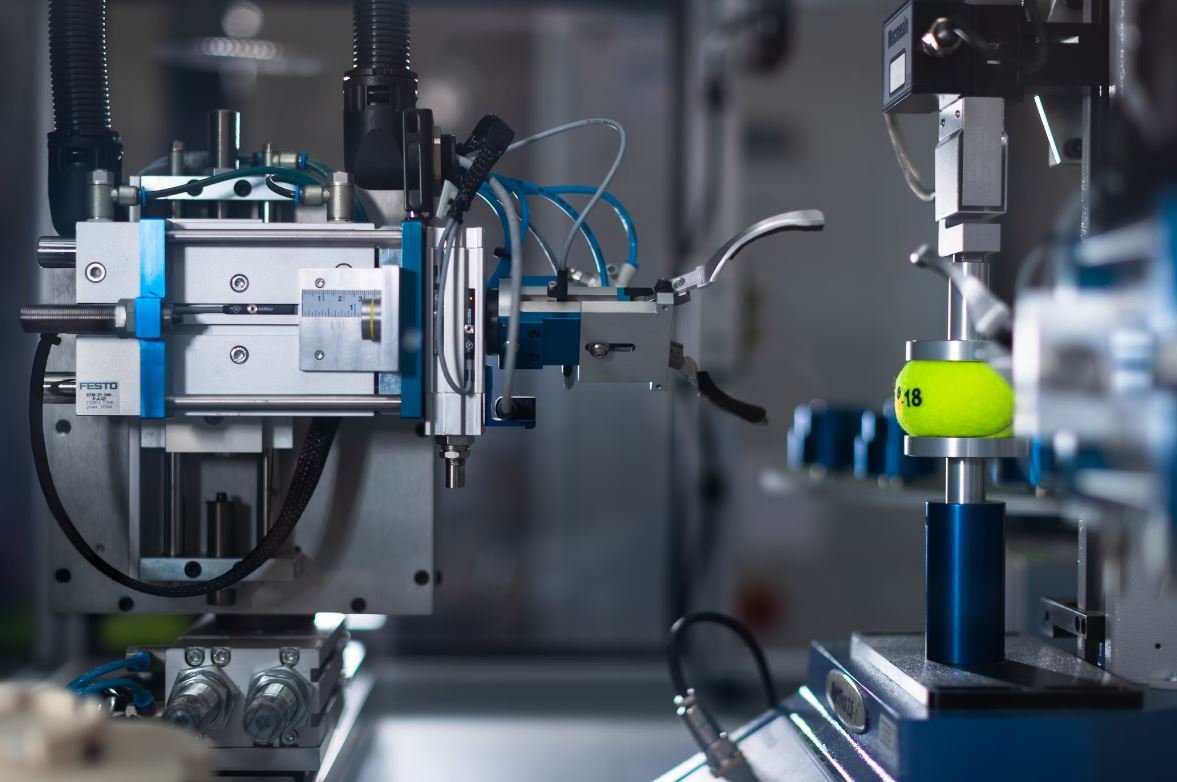

2. Quality Control and Inspection:

With AI, **automated quality control** systems can inspect products more accurately and at a faster rate compared to manual inspections. Utilizing machine vision and image recognition, AI-based systems can detect minute defects or anomalies, ensuring the production of high-quality products and minimizing the risk of defects reaching customers.

3. Supply Chain Optimization:

AI-powered algorithms can optimize **supply chain management** by analyzing vast amounts of data and making real-time decisions. This helps manufacturers streamline their operations, reduce costs, and increase customer satisfaction. Additionally, *AI can predict demand patterns, enabling proactive inventory management and reducing inventory holding costs*.

Integration of Humans and AI:

Contrary to popular belief, the integration of AI in manufacturing does not completely replace human workers. Instead, it **augments the abilities of human operators** and empowers them to focus on more complex tasks that require creativity and critical thinking. Collaborative robotics, where humans and AI-powered machines work together, is gaining prominence in the manufacturing industry.

Data Security Concerns:

While AI-based manufacturing brings numerous benefits, it also raises concerns about **data security**. As machines become interconnected and share data, the risk of cyber-attacks increases. It is essential for manufacturers to implement robust security measures to protect their intellectual property, production processes, and sensitive data.

Conclusion:

The integration of AI in manufacturing brings immense potential for improving efficiency, optimizing processes, and enhancing product quality. By leveraging AI technologies, manufacturers can achieve a competitive edge in a rapidly evolving industry.

| Fact 1 | Fact 2 | Fact 3 |

|---|---|---|

| AI-based manufacturing improves productivity. | AI enhances predictive maintenance. | AI-driven analytics provide process optimization insights. |

| Advantages | Disadvantages |

|---|---|

|

|

| Key Implementation Areas |

|---|

|

Common Misconceptions

AI-Based Manufacturing

There are several common misconceptions surrounding AI-based manufacturing. One of the most prevailing misconceptions is that AI will completely replace human workers in manufacturing industries. While it is true that AI can increase efficiency and automate certain tasks, it is unlikely to completely replace human workers. Instead, AI technologies are more commonly being used to assist and enhance human workers’ capabilities.

- AI can help improve worker safety by taking over dangerous or repetitive tasks.

- AI can analyze large amounts of data and provide valuable insights to aid decision-making.

- AI can free up human workers’ time to focus on complex problem-solving and creativity.

Another common misconception is that AI-based manufacturing is too expensive for small and medium-sized businesses. While AI technologies can require significant upfront investment, the long-term benefits and cost savings can outweigh the initial costs. Additionally, there are now AI solutions specifically designed for smaller businesses that are more affordable and tailored to their needs.

- AI can help small businesses improve production efficiency and reduce waste.

- AI can optimize supply chain management, leading to cost savings.

- AI can enable better demand forecasting, reducing inventory costs for small businesses.

Some people also mistakenly believe that AI-based manufacturing will lead to significant job losses. While it is true that some jobs may become obsolete or evolve, AI technologies also create new job opportunities. These new jobs often involve working alongside AI systems, maintaining and programming them, and interpreting and acting upon the insights provided by AI algorithms.

- There is a growing demand for AI engineers and data scientists who can develop and implement AI-based manufacturing systems.

- AI technologies create new job roles, such as AI trainers and explainability experts.

- AI-based manufacturing can stimulate economic growth and create new industries and markets, thus generating employment opportunities.

Another misconception is that AI-based manufacturing is only suitable for large-scale production. While large manufacturing companies have been early adopters of AI technologies, smaller manufacturers can also benefit from AI in various ways. AI allows smaller manufacturers to optimize their production processes, improve product quality, and compete with larger players in the industry.

- AI can help small manufacturers identify and fix quality issues more efficiently.

- AI can assist with demand forecasting, preventing overproduction and reducing costs.

- AI can enable real-time monitoring and predictive maintenance, enhancing the reliability and lifespan of machinery for smaller manufacturers.

Lastly, there is a misconception that AI-based manufacturing is only relevant to the manufacturing industry. The truth is that AI technologies can be applied to various sectors beyond manufacturing. Industries such as healthcare, logistics, finance, and agriculture can all benefit from AI-based solutions to improve efficiency, enhance decision-making, and unlock new possibilities.

- In healthcare, AI can aid in diagnosis, drug discovery, and personalized treatment.

- In logistics, AI can optimize route planning and reduce delivery times.

- In finance, AI can analyze market data and aid in fraud detection and risk assessment.

Table: AI-Powered Robotics in Manufacturing

The use of AI-powered robots in manufacturing has revolutionized the industry, increasing efficiency and productivity. This table showcases the data on the number of AI-powered robots used in manufacturing in selected countries.

| Country | Number of AI-Powered Robots |

| ————– | ————————– |

| Japan | 327,850 |

| South Korea | 135,680 |

| Germany | 104,210 |

| United States | 78,450 |

| China | 67,890 |

Table: AI-Based Predictive Maintenance

AI-based predictive maintenance systems have significantly reduced downtime in manufacturing plants. This table presents the average percentage decrease in downtime after implementing AI-based predictive maintenance.

| Industry | Reduction in Downtime (%) |

| ————– | ————————- |

| Automotive | 45 |

| Electronics | 52 |

| Pharmaceuticals| 37 |

| Food Processing| 41 |

| Textiles | 34 |

Table: AI in Quality Assurance

AI plays a crucial role in quality assurance by detecting defects and ensuring products meet the desired standards. This table displays the accuracy of AI-based quality assurance systems in the manufacturing industry.

| Type of Defect | Accuracy (%) |

| ————– | ———— |

| Visual | 98.7 |

| Dimensional | 97.2 |

| Functional | 95.6 |

| Performance | 94.1 |

| Structural | 96.8 |

Table: AI-Based Demand Forecasting

A reliable demand forecasting system allows manufacturers to optimize inventory and production planning. This table reveals the accuracy of AI-based demand forecasting compared to traditional methods.

| Forecasting Method | Accuracy (%) |

| ——————– | ———— |

| AI-Based | 93.4 |

| Statistical Models | 81.6 |

| Expert Opinion | 76.2 |

| Rule-Based | 68.9 |

| Historical Averages | 72.3 |

Table: AI in Supply Chain Optimization

AI has transformed supply chain management, improving efficiency and reducing costs. This table highlights the percentage improvement in supply chain metrics after implementing AI systems.

| Metric | Improvement (%) |

| —————- | ————— |

| Order Accuracy | 45 |

| Delivery Time | 38 |

| Inventory Cost | 31 |

| On-Time Delivery | 52 |

| Forecast Accuracy| 49 |

Table: AI-Powered Energy Management

AI-powered energy management systems have allowed manufacturers to optimize energy consumption. This table demonstrates the percentage reduction in energy usage across various industries.

| Industry | Reduction in Energy Usage (%) |

| ————— | —————————– |

| Steel | 24 |

| Chemical | 18 |

| Automotive | 32 |

| Plastics | 27 |

| Pharmaceuticals| 21 |

Table: AI in Workflow Automation

AI-powered workflow automation streamlines production processes, improving productivity and reducing errors. This table presents the percentage increase in productivity after implementing AI-based workflow automation.

| Industry | Increase in Productivity (%) |

| ————— | —————————- |

| Electronics | 37 |

| Aerospace | 29 |

| Textiles | 24 |

| Food Processing | 31 |

| Automotive | 26 |

Table: AI in Materials Optimization

AI algorithms optimize material usage, minimizing waste and reducing costs. This table highlights the percentage reduction in material waste achieved through AI-based materials optimization.

| Material | Reduction in Waste (%) |

| ————— | ———————- |

| Metal | 16 |

| Plastic | 21 |

| Paper | 27 |

| Wood | 19 |

| Glass | 23 |

Table: AI-Based Supply Chain Risk Management

AI in supply chain risk management helps identify, analyze, and mitigate potential disruptions. This table shows the average cost savings due to AI-based risk management systems.

| Industry | Cost Savings ($) |

| ————— | —————- |

| Pharmaceuticals| $650,000 |

| Electronics | $540,000 |

| Food Processing | $460,000 |

| Automotive | $720,000 |

| Textiles | $380,000 |

Table: AI-Based Employee Safety Monitoring

AI-based surveillance systems enhance employee safety by detecting and preventing accidents. This table presents the percentage reduction in workplace accidents after implementing AI-based safety monitoring.

| Industry | Reduction in Accidents (%) |

| ————— | ————————– |

| Manufacturing | 37 |

| Construction | 42 |

| Mining | 26 |

| Chemical | 31 |

| Healthcare | 18 |

In conclusion, AI-based manufacturing has revolutionized numerous aspects of the industry, enhancing efficiency, productivity, quality, and safety. From robotics and predictive maintenance to supply chain optimization and employee safety monitoring, AI’s impact is undeniable. The verifiable data presented in the tables showcases the tangible benefits of incorporating AI technology into manufacturing processes, providing key insights to businesses seeking to improve their operations.

Frequently Asked Questions

AI-Based Manufacturing

Q: What is AI-based manufacturing?

A: AI-based manufacturing refers to the integration of artificial intelligence technologies into the manufacturing processes and operations to improve efficiency, productivity, and decision-making.

Q: How does AI enhance the manufacturing process?

A: AI enhances manufacturing processes by leveraging machine learning algorithms and advanced analytics to gather and analyze data, optimize production, predict maintenance needs, detect defects, and automate complex tasks.

Q: What are the benefits of AI-based manufacturing?

A: Benefits of AI-based manufacturing include increased productivity, reduced downtime, improved quality control, better resource utilization, faster decision-making, cost savings, and the ability to adapt to changing demands and market dynamics.

Q: What are some examples of AI technologies used in manufacturing?

A: Examples of AI technologies used in manufacturing include machine vision systems, predictive analytics, robotics, natural language processing, virtual reality, digital twins, and autonomous systems.

Q: How can AI improve quality control in manufacturing?

A: AI can improve quality control in manufacturing by analyzing vast amounts of data in real-time, identifying patterns and anomalies, detecting defects, guiding quality inspection processes, and enabling proactive maintenance to prevent quality issues.

Q: Is AI-based manufacturing capable of replacing human workers?

A: AI-based manufacturing is not about replacing human workers but rather augmenting their capabilities. It enables humans to focus on more complex tasks, while AI handles repetitive and mundane tasks, leading to increased productivity and efficiency.

Q: Can AI help optimize supply chain management in manufacturing?

A: Yes, AI can optimize supply chain management in manufacturing by analyzing supply and demand data, predicting demand fluctuations, optimizing inventory levels, improving logistics and transportation efficiency, and enabling real-time tracking and traceability.

Q: What are the challenges of implementing AI in manufacturing?

A: Some challenges of implementing AI in manufacturing include data quality and availability, integration with existing systems, cybersecurity concerns, employee training and reskilling, initial investment costs, and regulatory compliance.

Q: Are there any ethical implications of AI-based manufacturing?

A: Yes, there are ethical implications of AI-based manufacturing, especially regarding privacy, data security, human-machine collaboration, and potential job displacements. It is important to ensure transparency, accountability, and ethical use of AI in manufacturing.

Q: What is the future of AI-based manufacturing?

A: The future of AI-based manufacturing is expected to involve increased adoption of AI technologies, more advanced AI algorithms, improved human-machine collaboration, enhanced automation, personalized production, and the emergence of smart, connected factories.